Building a wooden shed is possible if you follow the instructions step by step. A video tutorial and some preliminary preparation will certainly help. A framed wooden shed is inexpensive when you factor in the materials, and building one yourself is quite simple, as long as you're prepared and set aside some time.

Building a wooden shed is possible if you follow the instructions step by step. A video tutorial and some preliminary preparation will certainly help. A framed wooden shed is inexpensive when you factor in the materials, and building one yourself is quite simple, as long as you're prepared and set aside some time.

Before you begin building a shed, some preparation is required. You need to determine where exactly on the property the utility building will be located. A prominent location isn't recommended; a remote corner of the property, a space behind a house, or near a fence would be ideal. Pay special attention to the fact that the access to the shed must be clear: don't clutter the area or create garden beds or flower beds there.

Tips for choosing a good location to build a shed yourself:

- A high elevation is ideal for the structure, providing immediate protection from spring floods and heavy rains. A structure on such a site will last for a long time.

- When choosing a project and having it approved, you must immediately decide on the width of the entrance door: it must be suitable for the specific wheelbarrow used by the gardener for gardening.

- You can use any materials for the work; a shed made of planks or timber looks great and is easy to use. For the foundation, you can confidently choose a precast, columnar, or even a monolithic foundation.

- As for the final shape, there are no strict rules here either, and it's worth choosing structures that suit your needs. The easiest way to build shed with a pitched roof, but other types of roofs are also acceptable, it all depends on financial capabilities.

About the advantages of a frame barn

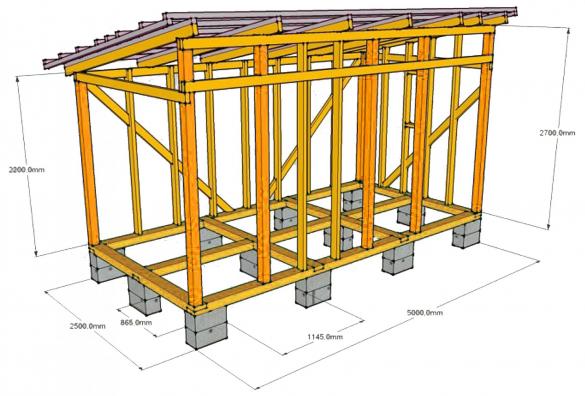

This step-by-step guide demonstrates that a frame shed is a great option because you can buy ready-made parts and then quickly assemble the structure. This project is easy to implement on your own, and even a novice builder can handle the job. Furthermore, the structure is durable, and if you choose the right location on your property, you can use the shed for years to come.

A huge advantage is the speed of construction. The construction manual indicates that beams, boards, nails, and metal angles are all needed, along with about a week's construction time. No additional rafter system is required!

Assembling the base

A step-by-step plan for constructing such a structure can be found in the video accompanying this material. However, some crucial initial stages of the work also require special attention. The soil under the shed should be moistened and compacted. Repeat this process several times until the soil has completely settled.

Advice! Using a long level, you should further check the levelness of the ground surface. Once this is confirmed, you can proceed with construction.

Cover the ground with a sand and gravel bed and compact it further. Mark out the approximate perimeter of the future shed. Install concrete blocks at the corners of the perimeter. A wooden frame is assembled on these blocks (fasten with anchors, drilling holes in the concrete blocks). Assemble the floor joists separately, keeping in mind that some will be under the walls. The floor needs to be well insulated; this is also an important step that shouldn't be ignored.

Which floor insulation should you choose?

- Mineral wool is considered widespread and easy to install, and its low cost is a major advantage. It is typically sold in packs and should be laid on a layer of roofing felt or regular polyethylene film. Carefully lay the mineral wool slabs into the floor spaces. It is also recommended to treat the floor joists with anti-rot impregnations and special antiseptics. You can lay several slabs in a layer for greater insulation, but do not compact the material, as it will quickly lose its insulating properties.

- You can also use polystyrene foam for insulating the barn floor. For its installation, you'll also need wooden sheathing, then a layer of waterproofing. The material is easy to work with because it doesn't warp and isn't susceptible to mold or mildew over time. Any gaps between the slabs can be sealed with foam.

- Expanded clay can also be used to insulate the floor of a shed. This requires creating a lower formwork and providing a waterproofing layer. Expanded clay should be poured into each section created in the formwork. The layer of this material should be at least 15 cm thick, otherwise the thermal insulation will be poor. This material must also be leveled; it should not be higher than the sheathing.

Walling

To erect the walls, use the corners of the posts that were previously used for support. Additionally, everything must be checked with a level and then securely fastened. The posts are attached to the frame using special brackets, then a frame is installed on top. A columnar foundation is built around the perimeter of the selected post. As a reminder, any type of foundation can be chosen for this type of utility building.

The finishing touches include installing doors and window frames. While a shed doesn't necessarily need many windows, it does need some light. Exterior cladding is essential, with overlapping boards nailed in place. Insulation from below should be considered separately; experts recommend membrane insulation in this case. Corrugated boards can also be used for insulation from below.

The interior also requires additional paneling. The walls should be insulated and waterproofed, and then the paneling can be made of fiberboard or chipboard, depending on your budget and taste. Often, this structure is used not only as a storage shed but also as a workspace. In this situation, it is recommended to additionally panel the interior with clapboard.

Advice! If year-round warmth isn't essential, a single layer of sheathing is sufficient. If a thermally insulated structure is desired, a double-layer sheathing should be used.

The built barnA house built primarily from wood is convenient and practical. If you're completely new to construction, you should definitely prepare for the project by reading additional materials on our website and, of course, carefully watching several videos on the topic. It's worth mentioning some of the disadvantages of wooden construction. While they're few, they do exist. First and foremost, remember that wood burns vigorously and easily.

Like any natural material, wood rots and is susceptible to damage from various insects. Modern construction methods can minimize these problems; wood can be treated with preservative pastes, organic solutions, or traditional oil-based preservatives during construction. Wood is susceptible to moisture, and over the years, this exposure can cause it to shrink, swell, and warp.

Alexander

Why insulate the floor in a barn?