To get an early harvest and then enjoy ripe and tasty vegetables throughout the gardening season, regardless of the weather, many gardeners build greenhouses on their plots. manufacturing greenhouses Previously, polyethylene film was widely used, but today it has been successfully replaced by a material such as polycarbonate.

To get an early harvest and then enjoy ripe and tasty vegetables throughout the gardening season, regardless of the weather, many gardeners build greenhouses on their plots. manufacturing greenhouses Previously, polyethylene film was widely used, but today it has been successfully replaced by a material such as polycarbonate.

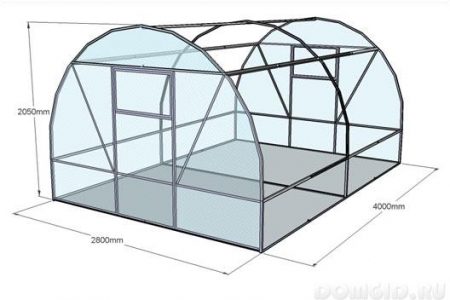

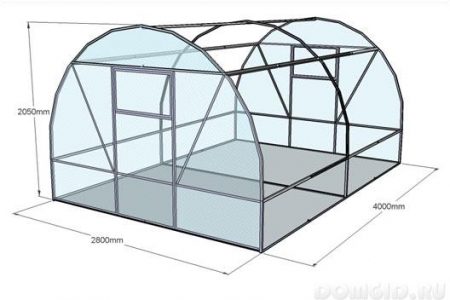

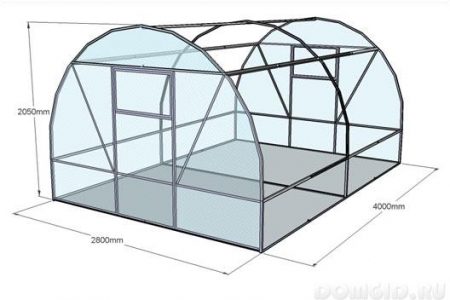

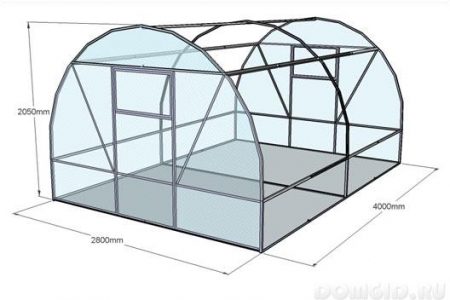

In this article, we'll explore how to build a polycarbonate greenhouse yourself using profiles, drawings, and other aspects of constructing this important yet simple structure. What's so great about polycarbonate compared to film? It's durable and doesn't need to be replaced every year. Once built, with proper care and maintenance, it can be used for many years without any problems.

The video instructions for this material provide detailed drawings and other details on how to build a polycarbonate greenhouse yourself using profiles. However, below we'll cover key points that are often not covered in videos but have important theoretical and practical significance.

About cellular polycarbonate

This versatile greenhouse material consists of two-layer plastic sheets of varying thicknesses. For greenhouses, sheets are 5 mm thick and measure 6 x 2.1 meters. They can be easily cut to the required size.

Advantages of polycarbonate for greenhouses compared to film or glass:

- High impact resistance. Even compared to glass, polycarbonate is two hundred times stronger, not to mention film.

- Complete protection of plants from exposure to ultraviolet rays.

- It tolerates temperature fluctuations well. Temperatures range from minus forty degrees Celsius to plus sixty degrees Celsius.

- The natural diffusion of sunlight through the material means that plants are less likely to get sunburned while inside the greenhouse.

- Plastic, as noted at the beginning, has two layers. This means the greenhouse will be well insulated in terms of thermal conductivity.

- Polycarbonate greenhouses are easy to build and maintain. Self-tapping screws are suitable for fastening the structure.

- Polycarbonate is lighter than glass, making transportation, installation, and construction of the greenhouse simple and quick.

- The material in question does not accumulate dust. Some dirt can be easily and quickly removed with just water.

- Does not burn; if exposed to fire, polycarbonate will melt but will not ignite.

- In terms of cost, the final structure can be compared to a glass version, but this type of greenhouse will have many more advantages, and installation is much easier.

How to care for polycarbonate

The photos and drawings in this article demonstrate how to build a polycarbonate greenhouse yourself using profiles. To ensure the structure serves you well for a long time, it's essential to follow certain material care guidelines. Avoid using abrasive pastes, chlorine, or alkalis to clean the surface: simply use clean water, or a little laundry soap. caring for tomatoes in a polycarbonate greenhouse.

To prevent mold and ridges from forming on the polycarbonate surface, it's important to maintain the end face of the polycarbonate, ensuring it's protected from moisture and insects. In winter, try to avoid ice buildup, as it can cause deformation of the structure.

Important information about greenhouse design

We'll discuss the plans for a DIY polycarbonate greenhouse made from profiles, along with the assembly instructions and drawings, below. First, you need to create a specific drawing to immediately determine the exact location on the site where the structure will be built. A greenhouse requires ample space, so there shouldn't be any trees or other structures nearby. Good ventilation, light, and heat should be ensured.

Greenhouse shape options depending on specific conditions and the selected design:

- To save on materials and also help conserve heat, you can build a greenhouse next to the wall of a building. That is, attach the structure to an existing structure on the site.

- Depending on the roof shape, the greenhouse can be single-pitched or double-pitched.

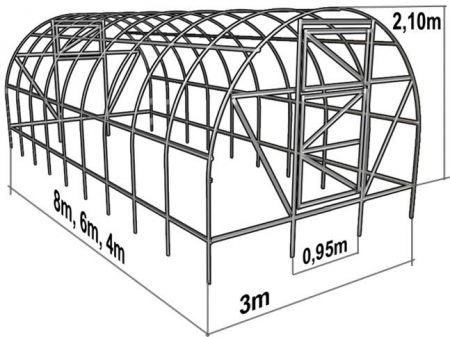

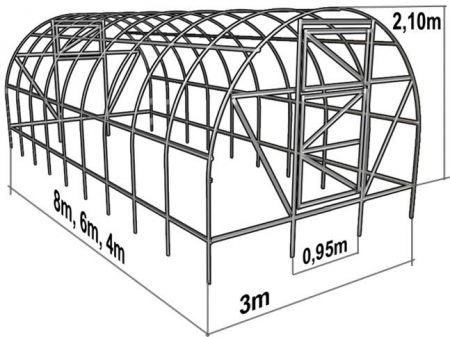

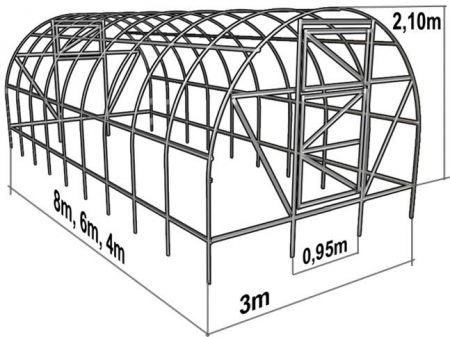

- An arched roof is quite common. However, making one from polycarbonate is quite difficult. A special pipe bender is required, or you can buy ready-made arched structures, but these are quite expensive.

- For this type of greenhouse, choosing and constructing the right foundation is crucial. The strength, practicality, and durability of the future structure depend on this initial stage.

Construction technologists

To build a polycarbonate greenhouse yourself, you can use a wood, plastic, or even metal frame. It's crucial to include ventilation openings in the greenhouse right away: windows and doors.

An arched roof further increases the air volume within the structure, which positively impacts crop growth and development. A built-in lever system is an additional complication, but it allows for opening roof vents, which is extremely convenient. The size of such vents should be at least one-quarter of the entire roof surface. Doors are also installed on the sides of the structure, not just the end, to ensure good air circulation.

Square tubing and metal corners are ideal for the frame. First, build the frame and then attach it to the finished foundation. Paint the metal structure before installing it. get rid of spider mites in a greenhouse.