Country house owners put a lot of effort into keeping their rooms warm and comfortable during the winter. A good owner strives to provide the same conditions for their pets to keep them warm in the freezing cold. For this reason, it's important to properly insulate a dog house for the winter. But first, it's important to understand the best materials for this purpose.

Rules for insulating a kennel

When insulating a dog house for the winter, consider your pet's breed. Short-haired dogs require more warmth than their long-haired counterparts. Dog houses often freeze, leak, and are windy. To keep your pet warmer in the winter cold, When arranging his home, the following nuances must be taken into account:

- the entrance to the kennel is located where wind movement is minimal;

- the structure is assembled from natural wood;

- During rain, water should not seep inside, so the kennel is either placed on an elevated surface or is well waterproofed;

- The booth should be made according to the size of the pet, it should not be cramped, but too much space is also undesirable.

Thermal insulation should provide protection from wind, moisture, and frost. If the dog house can be easily dismantled, then internal insulation is preferable. Once the structure is fully assembled and cannot be disassembled, attention should be paid to external insulation. In the latter case, a final cladding will be required; otherwise, the house will look unattractive and spoil the appearance of the property.

Selection of material

Since the pet's home is being insulated, certain requirements must be taken into account during installation. The walls of the kennel must be insulated with a material that is not easily damaged, otherwise it will quickly deteriorate. Furthermore, it is advisable to use natural thermal insulators that do not emit harmful compounds and will not harm the pet's health.

It's also important to properly and reliably insulate the interior of the structure, otherwise some materials may irritate the animal's respiratory system. Therefore, it's important to choose the right insulation material carefully. It's worth considering the most common materials and understanding the characteristics of each.

Mineral wool

This material is considered one of the most popular. It's used not only for insulating living spaces but also for insulating dog houses. In the latter case, it must be used with extreme caution, as the animal can damage the mineral wool, causing it to lose its original technical properties. Furthermore, it can be harmful to the pet's health.

Working with mineral wool is quite challenging due to the small footprint of the kennel. However, if you choose this material, it must be applied correctly:

- It is strictly forbidden to use glass wool as insulation;

- The thermal insulation layer must be waterproofed.

Foam sheets

Foam plastic is considered an excellent insulating material for dog houses; it has much better thermal insulation properties than mineral wool. Furthermore, it's less susceptible to external influences, so there's no need for additional waterproofing. There are several types of material, which are ideal for setting up a kennel:

- penoplex;

- expanded polystyrene.

Roll-type thermal insulators

Polyethylene film is a roll-type thermal insulation material suitable for insulating a doghouse. This material can be easily secured to the walls and ceiling of the structure using a standard construction stapler. There are also roll-type thermal insulation materials that already have an adhesive backing.

Another option is penofol. It also has good thermal insulation properties, but requires additional cladding as it is susceptible to mechanical stress, and any damage can degrade its performance.

Application of felt

This natural fabric is ideal for insulating a dog house. Felt offers increased safety and is affordable, making it an ideal solution for a dog house.

Thanks to its vapor-impermeable properties, the material is moisture-resistant, meaning the dog's shelter will always be dry and warm. It's windproof and doesn't require additional protective layers. Regular nails with small heads are suitable for fastening.

Once the insulation has been selected and purchased, installation can begin. The process is divided into three stages, and it's worth examining each in more detail.

Bottom and floor covering

The first step is to insulate the floors and protect the bottom of the structure. To do this, turn the doghouse upside down. Afterward, clean the wood of any debris and treat the surface with a special preservative to protect it from deterioration. Then, cover the bottom with roofing felt. This completes the external protection of the flooring.

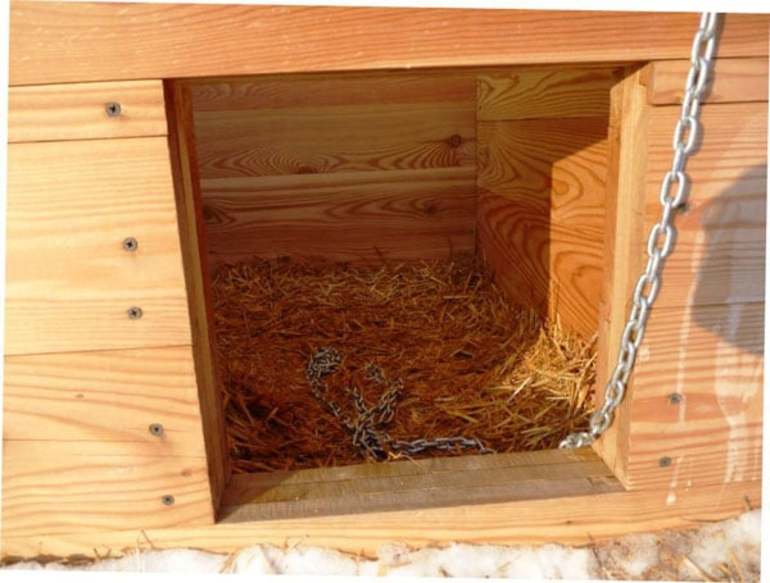

After this, return the frame to its original position and begin the interior finishing. A waterproofing membrane is laid on the floor; roofing felt can also be used for this purpose. When installing, keep in mind that the material should be laid with a slight overlap to avoid gaps and cracks that cause drafts. A stapler can be used as a fastener.

Lastly, assemble the finished floor, which can be made from any old boards, plywood, or OSB boards. After that, add additional insulation to protect the doghouse from the winter cold.

Insulation is applied to the area where the frame will be installed. To do this, dig a hole 20-30 cm deep. Fill it with a layer of expanded clay or gravel, creating a cushion. A sheet of roofing felt is laid on top, and then the kennel is installed. This structure will protect the kennel from possible floor freezing or moisture leakage.

Walls of the structure

Each insulation material is installed differently; the exact installation instructions are always included with the material. But in any case, the following activities are always carried out:

- They begin work by preparing the surface of the walls, cleaning them and then treating them with special compounds;

- if necessary, lay a layer of waterproofing;

- they produce insulation sheathing;

- secure the vapor barrier material;

- perform cladding.

Ceiling and roof

If the kennel is installed in a dedicated enclosure with a built-in canopy, then any roof can be used, and insulation is not even a consideration. In all other cases, a pitched roof with a removable or collapsible design is best.

The upper floor is insulated using the same method as the floor. First, a polyethylene film is attached to act as a waterproofing layer, then the insulation is laid. However, there's no need to provide additional protection in this area, as the dog won't damage it. It's advisable to line the inner slopes with a good insulating material around the perimeter.

Installing the curtain

Once the booth is fully insulated, it needs to be equipped with a curtain that will maintain an optimal temperature inside. The following fabrics are suitable for making curtains:

- Tarpaulin. This material is extremely durable. During production, its base is treated with a special flame-retardant compound. A distinctive feature of this fabric is its elasticity, making the curtain easily adjustable to the size of the entrance.

- Felt fabric. Made from a synthetic fiber, it perfectly retains heat inside the kennel. Felt can be easily cut to the required length, without the risk of fraying or tearing edges.

When making a fabric door, it is worth considering that it should completely block the entrance, but at the same time not interfere with the pet. It is advisable to first mark the required dimensions And only then cut the fabric. It's best to leave small allowances of 5 cm on the sides and 10 cm at the bottom. It's best to secure the fabric with a wooden strip and screws, so the dog can't accidentally tear it off.