Potato planters come in different varieties: manual and two-row. This device allows for quick and easy potato planting over large areas of land. This machine is indispensable in agricultural settings.

A potato planter is a device that makes gardeners' work easier and is designed for planting potatoes. It comes in various designs, including manual and double-row. You can even make one yourself for a walk-behind tractor. This device allows you to quickly plant potatoes over large areas.

Purpose of the potato planter and its operating method

All potato planting devices, whether a walk-behind tractor potato planter or another type, serve the same purpose. They facilitate the spring planting process and almost completely automate it.

Functions of planters:

- creating a harrow for sowing;

- digging a hole for tubers;

- sorting tubers into holes;

- filling in holes;

- soil fertilization (optional);

- creation of landing rows (optional).

Advantages of the devices:

- speed up potato planting several times;

- allow you to create perfectly even rows;

- plant tubers at the optimal depth;

- reduce the physical stress on a person;

- allow you to fertilize the soil at the same time as planting seeds.

The only drawbacks are the device's bulkiness (it's difficult to operate manually) and the high price of the finished product. But if you can't afford a branded unit, there's always the second option: making your own manual potato planter.

Types of devices

The following types of units for rapid potato planting are distinguished:

- potato planter for walk-behind tractor;

- potato planter for a mini tractor

- manual potato planter.

This classification is based on the method of mounting the unit's controls. A device attached to a walk-behind tractor or minitractor can operate automatically. Simply point the equipment in the desired direction (some vehicles can also be adjusted automatically, allowing potato planting to proceed without any human intervention). Manual planters are distinguished by the fact that they must be operated manually, not attached to agricultural machinery.

A manual option is the best choice for a small farm. If you need to sow a large area, it's better to choose a unit attached to a walk-behind tractor or mini tractor. A mini tractor covers a larger area in a shorter period of time. For budget-friendly cultivation of large areas, a DIY potato planter for a walk-behind tractor is suitable.

How a manual potato planter works – video:

Units are also differentiated by the number of rows that are sown simultaneously:

- single-row unit;

- double row potato planter.

The two-row one is more convenient to use because it allows you to plant two rows of potatoes (the distance between the rows is adjustable, approximately 70 cm).

The final division is by manufacturing method. You can purchase a ready-made product. Prices for ready-made planters start at 7,000-8,000 rubles. If you need to cut costs, a homemade potato planter, custom-made to your specifications, will do the trick. How to make your own is described below.

A brief overview of finished models

If your budget allows, it's always better to buy a ready-made unit. They look better, last longer, and may come with a warranty. They often have important additional features. Below are descriptions of the most common potato planter models.

Potato planter KS-1A

Designed for walk-behind tractors with a power output of 10 horsepower or more (i.e., heavy-duty walk-behind tractors). The body is bright red, and the frame is black. The price is 8,000-8,500 rubles.

Brief characteristics:

- weighs 33 kg;

- holds up to 34 liters of tubers;

- It can process up to half a hectare per hour.

Despite the fact that the planter is attached to the motor unit, it is considered optimal for small fields and even summer cottages.

Potato planter KC – 1

The price of this unit is already higher than the previous one – 12,400 rubles. Purchasing in bulk can reduce costs.

The increased price is due to the machine's lighter weight, weighing only 25 kg. However, its productivity is half that of the KS-1A: only 0.2 hectares per hour. Its primary purpose is to cultivate small areas in summer cottages and farmland.

Made of sheet material.

Potato planter KCM – 1

The price of the product is 9,300 rubles. It is intended for the following walk-behind tractors:

- Beam;

- Cascade;

- Neva;

- Oka.

Can be attached to other blocks if the mount is suitable.

Brief characteristics:

- weight 33 kg;

- processing speed – 0.25 ha per hour;

- holds 34 liters of potatoes.

This version is practically no different from the KS-1A.

Potato planter KCM-1A

The KSM-1A also attaches to walk-behind tractors. It's suitable for both heavy-duty and medium-duty units (under 10 hp). Like other models in the KS series, it features a distinctive red body.

Weighing just 33 kg and boasting a 34-liter tank capacity, it can process up to 0.25 hectares per hour. Suitable for small farms.

Potato planter KCT – 1T

It comes well equipped with tanks for applying mineral fertilizers. Like other models, it's suitable for cultivating small areas. Unlike other models in the KS series, it's painted a bright blue.

How to create a unit with your own hands

A homemade potato planter can be made from ordinary scrap metal, although it is better to use new materials.

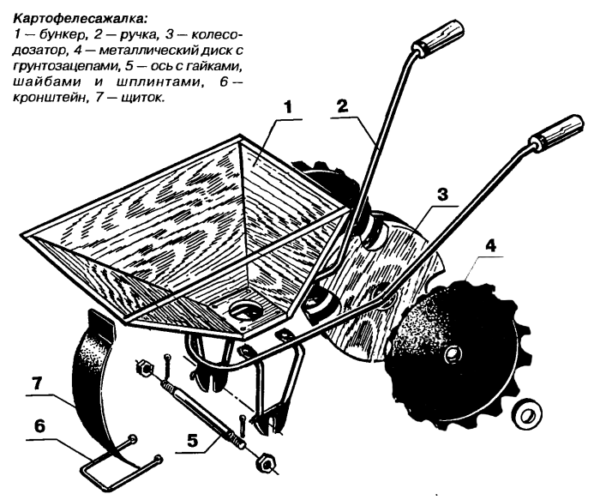

You can make various versions of this device—a DIY potato planter for a mini tractor or for a walk-behind tractor. The most popular option is a manual one. It's inexpensive and doesn't require any additional expensive equipment. However, planting potatoes with this device often requires two people (see above). It's necessary to constantly place the tubers in a transport net, otherwise the unit will simply run empty. Maintaining the unit requires a lot of effort.

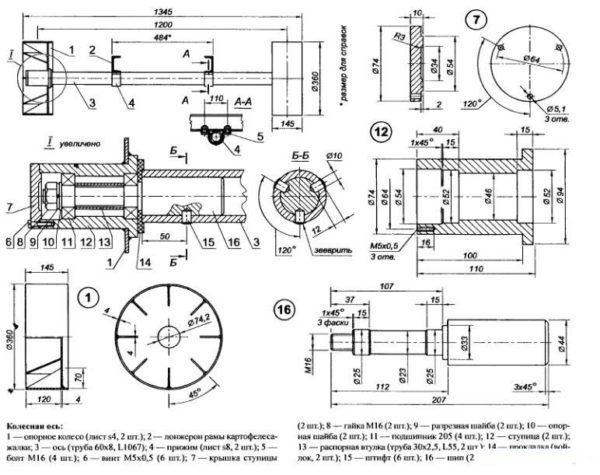

So, how do you make your own unit? You'll need the following materials:

- potato bin plywood;

- drying oil or other composition for wood treatment (impregnation, antiseptic);

- reinforcing bars;

- steel sheets;

- metal corner;

- channel;

- wheel axles.

Additionally, you'll need seat materials (if you're making one for a walk-behind tractor)—foam rubber, synthetic padding, fabric, or faux leather. A rubber pad inside the wooden tank itself is also needed. This will soften the friction of the seed against the tank, preventing damage to the tubers.

First, a bin is made. You'll need plywood, brushes, wood stain, and angle iron. Metal angle irons hold the bin together. The bin should be inclined, so the tubers will gradually flow to the dispenser, and from there, into the holes dug with a bucket.

After the tank, the main frame must be constructed. It must be steel, otherwise it will sag under the weight of the tubers or rot due to constant moisture. The tank is attached to the frame (on top), and should already be painted before attaching.

The ripper is created separately. It is made from pipes and spikes, as well as wheel axles. The ripper is located at the front of the unit, as it prepares the soil for digging holes.

Other mandatory parts of the unit:

- a transport belt for tubers, which is made from a chain and protrusions mounted on it to hold the tubers;

- steel sheet wheels with hubs;

- steel sheet furrow cutter;

- Front and rear counterweight for driving on inclined surfaces.

All parts should be welded rather than fastened together by other means. Large bolts are permitted when using angles.

A seat is needed if the machine is not handheld but is attached to a walk-behind tractor. It must be durable, preferably with a metal base. A sheet of plywood is covered with fabric, with a soft material placed between the fabric and the base.

Reviews of homemade planters

Vitaly Ts., 49 years old, agricultural worker:

"I made my own potato planter to make my job easier. The whole thing cost about 2,000 rubles. I'm very happy with the result. I made a manual version. Planting by hand isn't as convenient as using a walk-behind tractor or a tractor, but for the price, it's a great "craft." It plants evenly, and I was able to adjust the spacing between the beds."

Evgeny F., 30 years old, entrepreneur:

"I plant potatoes on my farm every year. Previously, I had to hire a lot of labor for planting, which was expensive. But when I welded a simple planter myself, the costs immediately dropped tenfold. Now, two workers can plant an entire field in a day."

Afanasy K., 52 years old, vegetable grower:

"I made a potato planter because I can no longer bend over and dig furrows myself due to my health. Considering I used improvised materials, I spent almost nothing. Moving the device effectively requires a lot of effort, but it's still much easier than digging the holes myself."

A potato planter, whether homemade or purchased ready-made, significantly simplifies the process of planting tubers. Therefore, it is recommended that all farmers, owners of large potato plots, and agricultural entrepreneurs purchase or make one themselves.

How to choose a saw for your garden: everything every gardener needs to know

How to choose a saw for your garden: everything every gardener needs to know Robotic Lawn Mowers: Should You Trust Your Grass to These Automatic Helpers?

Robotic Lawn Mowers: Should You Trust Your Grass to These Automatic Helpers? Which garden hose is best? All the aspects to consider

Which garden hose is best? All the aspects to consider Electric vs. Gasoline Trimmers: Which One to Choose for Your Yard?

Electric vs. Gasoline Trimmers: Which One to Choose for Your Yard?