A mechanical agricultural assistant, paired with a wheeled tractor, spreads organic fertilizers across fields. The organic matter is evenly distributed across the field. The organic fertilizer spreader handles large quantities of peat, compost, sludge, and poultry manure.Fertilizer spreaders are a modern necessity in industrial agricultural technology. They mechanically apply fertilizers to the soil in dried or granular form. The broadcast method is designed for uniform application of dry fertilizers. The industry produces a wide range of organic fertilizer spreaders. They can evenly distribute fertilizer for future crops onto unplowed soil, so that the soil is saturated with nutrients, rests over the winter, and can confidently sow and plant crops for the next harvest in the spring.

Organic Fertilizer Spreader: How to Apply Solid and Liquid Fertilizers

Russian companies are confidently leading the world in the production of organic fertilizer spreaders. Domestic equipment is significantly superior to chassis-and-body systems imported from China and Poland. The operating principle of domestic organic fertilizer spreaders allows for two types to be distinguished: trailed and mounted spreaders. Manufacturers offer a wide selection of spreaders for the efficient application of fertilizer in fields. Each model has its own operating principle and is designed for different tasks, depending on the density of the fertilizer being applied.

Description of the organic fertilizer spreader

Trailed units are popular with farmers working large areas of land. They can simultaneously load several trailers and park them at the edge of the field. The tractor driver distributes fertilizer from one trailer, then parks the empty trailer at the edge of the field, attaches the loaded trailer, and continues working without wasting time loading. Mounted units are designed for the comprehensive delivery of various fertilizers, including liquid ones, in predetermined proportions. They are used for cultivating small plots of land.

Organic fertilizer spreader

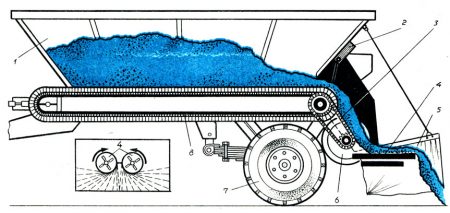

The structural foundation is a chassis frame made of durable high-alloy steel and steel alloys. The frame is equipped with a trailer attachment for a towing tractor. The frame supports the body structure, which is equipped with a scraper conveyor that transfers the fertilizer to the spreader. The conveyor also speeds up unloading when the trailer is used as a trailer for transporting various bulk materials.

The conveyor system consists of four chains with scrapers secured with clamps. All chain lines are tensioned and adjusted with bolts. The conveyor system is powered by the tractor's power takeoff shaft. The feed from the conveyor rollers is first directed to the chopping drum, then to the spreading drum.

The chassis consists of two pairs of wheels equipped with a balance beam and support system. The bogie brakes are connected to the tractor brakes via an adapter, and the system is activated by the driver pressing a pedal in the tractor cab.

RO-6

The ROU-6 organic fertilizer spreader is manufactured by the long-established BelotserkovSelMash company, which manufactures a wide range of agricultural machinery for various purposes. The unit is a four-wheel trailer-type chassis with a body housing the spreading mechanism, connected to the tractor's power take-off shaft. When the spreader is removed, all that remains is a convenient trailer for any tractor.

The purpose of the machine

The modern design of the ROU-6, a fertilizer spreader for industrial use, makes it convenient and widely popular. Its primary purpose is to precisely distribute fertilizer. These machines have been in use for a long time, and even at headlands, the tractor evenly distributes the fertilizer.

Using the ROU-6 spreader optimizes agricultural production, increases yields, and allows for the application of various fertilizers. The spreader precisely doses the fertilizer and distributes it evenly across the field.

Pros and cons

Tractor equipment significantly reduces the cost of mineral fertilizers because they are spread across the field at precise rates as recommended in the Fertilizer Application Instructions. Organic fertilizers, such as composted manure, are recommended to be spread across the entire field; late cultivation is permitted.

The main advantages of the machines:

- convenient fertilizer feeder;

- Automatic control of fertilizer application dosage is provided;

- spreading is done efficiently and at virtually no cost;

- the units are easy to operate;

- the units are easy to use;

- It is possible to use the chassis as a regular transport trolley.

Advantages of ROU-6:

- adjustable transport speed;

- mechanized application of fertilizers to the soil;

- fertilizer spreading width – up to 8 m;

- the spreading device has the principle of continuous application of fertilizer;

- fertilizers are spread efficiently and evenly;

- Due to this, wheeled tractor rentals compact the soil less.

When fertilizer spreading isn't required, the spreader unit is removed from the body, and the trailer is used as a spacious cargo bed. The trailer retains its mounted conveyor, allowing for quick and easy unloading. The trailer is convenient and practical, allowing for effortless storage or transportation. The cost of vehicle maintenance is offset by the resulting harvest.

MZhT-F-11

The MZhT-F-11 liquid organic fertilizer unit is manufactured by the BobruiskAgroMash production association. It features a heavy-duty transport chassis with two pairs of wheels and a towing hitch for attaching to a towing vehicle. The chassis is equipped with a large tank with a capacity of approximately 11 tons of liquid, a centrifugal pump, and a dispensing device.

The purpose of the machine

The liquid fertilizer application tanker is designed to load itself and mix the components during transport when applying combined mixtures. When spreading liquid organic fertilizer over the field surface, the spreading device ensures a continuous coating of the liquid solution. Self-loading is ensured by a vacuum system and a hatch, allowing for autonomous loading.

The trailer tanker is controlled from the towing vehicle's cab, as the braking and electrical systems are connected. The MZhT-F-11 is successfully used for transporting process water, long-range irrigation of fields, washing equipment, and washing and watering roads.

Special applications! The tanker with a dispensing system and centrifugal pump is particularly suitable for extinguishing fires, including forest fires, as the wheeled tractor is maneuverable and can access hard-to-reach areas.

Pros and cons

Equipping the MZhT-F-11 with a spreading unit outperforms similar machines in terms of fertilizer application and dispersion. This improves the quality and uniformity of fertilizer distribution across the entire area, while minimizing nitrogen emissions. Using this unit increases fertilizer application productivity by 20% while simultaneously reducing labor input for pollination by 15-20%.

The MZhT-F-11 unit is equipped with a vacuum self-loading system, with a self-loading time of 4 to 7 minutes. Rapid self-loading is essential when using the machine to extinguish forest fires. The hose length allows for liquid pickup in bodies of water as deep as 2.5 meters. The tractor control unit is equipped with a spray metering unit, allowing for adjustable fertilizer application rates ranging from 10 to 60 tons per hectare, depending on the field preparation plan.

Bobruisk AgroMash manufactures tanks with various capacities, from four to 23 m³. Their design is fundamentally the same: a trailer or semi-trailer chassis for horizontal placement of a cylindrical tank with curved ends. The tank is equipped with a vacuum pump for filling, internal devices for mixing the various components of the mixture, and creating the necessary pressure for operation. The design also includes a distributor for spraying fertilizer.

How to apply solid and liquid fertilizers

Solid and liquid fertilizers are applied by various types of machines. For solid fertilizers, the ROU-6, PRT-7, and other units are used. Liquid fertilizers are sprayed by the MZhT-F-11 and its modifications.

The MZhT-F-11 spreader evenly distributes liquid organic fertilizers across the field surface by adjusting the angle of the spreader's deflector. The field width is also adjusted using the same method when spraying the liquid. Liquid organic fertilizers are unloaded using a centrifugal pump. After finishing work, the tractor forces the spreader to self-load, which is facilitated by a vacuum system.

ROU-6 machines distribute organic fertilizers in solid form across fields. The application rate depends on the speed of the machine and the activity of the conveyor mounted in the machine's body. Speed does not affect the uniformity of fertilizer distribution across the field, thanks to spreaders with centrifugal working elements.

Reviews

Gardeners have long believed in the benefits of organic fertilizers, creating their own compost bins and preparing solid fertilizers to fertilize their plots. Hand tools are becoming a thing of the past, and mini-equipment is appearing in gardens and homesteads.

Ivan, Kursk:

"I've spent my entire life working in the fields, using various agricultural machinery, and when I retired, I bought a mini tractor for my own garden. We have a large family and several vegetable gardens, so the tractor was a perfect addition. We also bought plows and harrows—everything we needed. But when I started thinking about fertilizing, I realized we simply couldn't do without a compact, small device. I also wanted a single unit capable of applying both liquid and solid fertilizers. I considered various options and settled on the Gardena Comfort 800. It's what they call a 'three-in-one': it also spreads seeds on lawns. Overall, I'm happy with the purchase. As an experienced farmer, I appreciate this type of equipment."

Ilya, agronomist of the Ivolga concern:

"Agricultural equipment manufacturers will always be in demand for their products because they don't stand still, constantly improving their models and developing modifications through the introduction of technical innovations. The improved ROU-6 fertilizer spreader allows agronomists to work with both ready-to-use granular and powdered fertilizers and with other materials such as peat and sapropel. With a single unit, we now have the ability to diversify fertilizer application and increase crop yields."

How to choose a saw for your garden: everything every gardener needs to know

How to choose a saw for your garden: everything every gardener needs to know Robotic Lawn Mowers: Should You Trust Your Grass to These Automatic Helpers?

Robotic Lawn Mowers: Should You Trust Your Grass to These Automatic Helpers? Which garden hose is best? All the aspects to consider

Which garden hose is best? All the aspects to consider Electric vs. Gasoline Trimmers: Which One to Choose for Your Yard?

Electric vs. Gasoline Trimmers: Which One to Choose for Your Yard?