The annual potato harvest can be quick and easy if you replace manual labor with specialized potato diggers for walk-behind tractors or mini tractors.

The annual potato harvest can be quick and easy if you replace manual labor with specialized potato diggers for walk-behind tractors or mini tractors.

The use of specialized equipment will not only significantly facilitate and speed up the potato harvesting process, but will also significantly preserve health and good physical condition, as it does not require the titanic physical labor of manual potato digging.

Potato digger for a tractor A walk-behind tractor (or motoblock) is an attachment that attaches to a walk-behind tractor or mini-tractor. Potato diggers have tines that dig up the soil as they move. As they move along the conveyor, potatoes are trapped between the tines. The tubers are automatically placed in a special container or ejected into the row spacing. The device automatically digs and clears the crop, leaving only the surface to be collected.

The device allows you to clear an area of land from crops much faster and more efficiently than using manual labor.

Potato digger for a walk-behind tractor You can buy one at a gardening or home improvement store, or you can make one yourself. How to make a potato digger We will definitely consider this in more detail below.

Advantages and disadvantages of homemade potato diggers

Make a homemade unit It's quite feasible and quite profitable. However, everything has its downside, so homemade tiller diggers do have their downsides, although they're not numerous.

Disadvantages of homemade potato diggers:

- The design process requires painstaking work, as drawings must be found. Even ready-made drawings found online sometimes require revision and customization;

- Weight of a homemade potato digger, handmade, There will be more. Manufacturers of ready-made potato diggers are optimizing their products as much as possible, using every opportunity to reduce their weight;

- A walk-behind tractor/mini-tractor consumes more fuel when using a homemade potato digger. The heavier the mounted potato digger, the more fuel it consumes;

The benefits of a homemade potato digger

- The cost of the unit is significantly lower as a result. Potato digging attachment Direct from the manufacturer, it's not cheap; not everyone can afford it. The cost of a potato digger is several times lower than a ready-made version;

- A custom design tailored to a specific site, soil, and the person who will be managing the process. As mentioned above, even a ready-made digger design is usually modified to take into account the site's characteristics, soil, personal physical strength, etc.

- Improvements are underway. The potato digger can be upgraded by adding additional components that can increase its efficiency;

As you can see, the disadvantages aren't too significant. At least, they don't outweigh the advantages of making your own potato digger.. However, if we are talking about huge areas, a potato digger for a tractor A walk-behind tractor from the manufacturer will still be more cost-effective. Homemade devices are more suitable for medium or small plots with a relatively small planting area.

Types of potato diggers

The units under consideration are divided into two main types: arrow-type and vibrating (screen).

Arrow potato diggers, also known as fan-type potato diggers, consist of a ploughshare with angled rods welded to it. This is the simplest type of device, capable of being attached to any walk-behind tractor or small tractor. A similar potato digger for a walk-behind tractor It's done quite simply.

A simple potato digger works by using a ploughshare to cut through a layer of soil, along with the harvested crop. The soil then falls back between the tines, leaving the tubers floating on the surface. This design is only effective on loose soils.

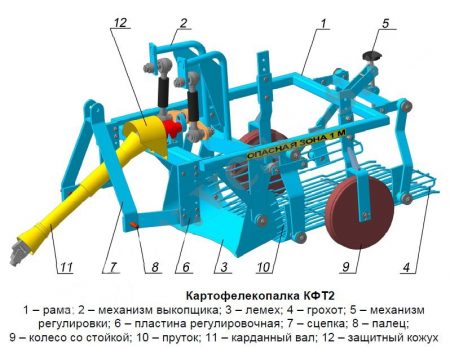

Vibrating or sieving potato digger The plough consists of two main parts: a share (plow) and a vibrating screen mounted on support wheels. As the unit operates, the share picks up some of the soil and tubers and throws them onto a screening grate. The vibrations sift the soil, leaving only the potatoes on the grate.

Despite its simplicity and ease of use, as well as its high productivity, building a homemade potato digger for a walk-behind tractor is complex and labor-intensive. However, any difficulties in the manufacturing process are ultimately worth it.

The most popular potato digger models

Today, there are several popular types of potato diggers: the standard KKM-1, the standard KKM-3, the standard Garden Scout, the vibrating Neva, and the vibrating Poltavchanka. Let's take a closer look at each model.

Simple potato digger for walk-behind tractor KKM-1

- The canopy includes a ploughshare and a seeding grid;

- The device is well suited for soft and medium soils with a moisture level of no more than 25%;

- The digging depth is 20 cm and the cultivation area is about 35 cm;

- The design's performance ranges from 0.05 hectares to 0.2 hectares per hour;

- KKM-1 weighs on average about 40 kg;

- The device travel speed is 1-2 km/h;

- The canopy is suitable for motorized units such as Neva, Kaskad, Salute, Favorit, etc.

Simple potato digger for walk-behind tractor KKM-3

Device The third-generation KKM-3 is similar in performance to the KKM-1, but has a number of improvements. For example, compared to the KKM-1, the KKM-3 has a larger working area—40 cm. The unit is operated by a single operator. The digging depth can be adjusted using support wheels.

This potato digger is for a mini tractor. is the most optimal option due to its weight - 40 kg.

Simple potato digger for Garden Scout walk-behind tractor

- It is a product of a Chinese factory;

- The width of the processing area is 40 cm, and the cultivation depth is 28 cm;

- The structure weighs 42 kg;

- The Garden Scout design has a productivity of up to 0.2 hectares per hour;

Vibrating potato digger for the Neva walk-behind tractor

- This compact vibratory potato digger is designed specifically for Neva motor units;

- It has a relatively small weight - 34 kg;

- The tillage depth is 20 cm, and the ploughshare width is 36 cm.

- The design’s productivity ranges from 0.15 hectares to 0.2 hectares per hour;

- The device travel speed is 1-2 km/h;

- The design has price advantages over competitors;

Vibrating potato digger Poltavchanka

- The design is suitable for medium-heavy soils, the moisture level of which can reach 30%;

- The nozzle weighs 34 kg;

- The penetration depth into the soil is only 18 cm, the coverage area of the ploughshare is 39 cm;

- The device travel speed is 2-3 km/h;

- The canopy is suitable for various types of walk-behind tractors and mini-tractors (Neva, Favorit, etc.)

- The level of the device's wheels can be adjusted;

How to make a potato digger for a walk-behind tractor

Making your own potato diggers is a rather labor-intensive and painstaking process. You can make one yourself in several steps. We'll cover each step in detail and explain how. How to make a potato digger for a walk-behind tractor with your own hands.

Tools for work

First, you need to prepare the tools you'll need to build your own potato digger for a walk-behind tractor, as well as other consumables.

The working tools that you cannot do without when assembling a potato digger are:

- welding machine,

- angle grinder,

- electric drill,

- square,

- level,

- perforated mounting plates,

- steel bolts with nuts.

Manufacturing of a vibrating potato digger

To make a homemade potato digger for a walk-behind tractor on a vibrational basis, we will need:

- The supporting structure is a metal channel;

- Steel sheets for making the ploughshare. The steel must be at least 5 mm thick.

- Steel or iron corners made of rolled metal;

- Steel or iron rods, preferably of small diameter;

- metal pipe

The design of the potato digger contains a frame, a suspension system, control rods, wheels or other moving units.

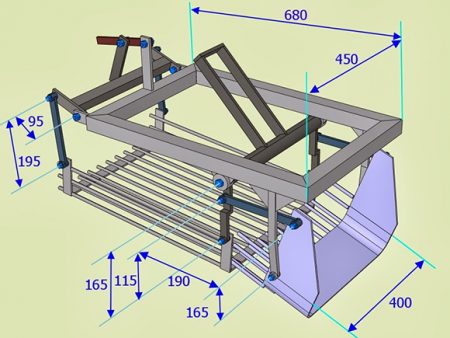

Step 1. The base of the vibrating potato digger

The process of making a potato digger for a walk-behind tractor with your own hands must begin with creating the base.

In order to weld the frame, A 40x40mm profile pipe will do. We'll use a 4-meter-long square pipe as a base, cutting it into 80cm and 120cm pieces. This length will be enough for four pieces, which will serve as support beams.

The support beams are welded at a 90-degree angle, creating a rectangular frame with sides measuring 0.8 m and 1.2 m. The frame is ready.

Step 2. Attaching the rods

To create the tie-rod mount, we take the aforementioned rectangular base. Weld a metal channel to it, one-third or one-quarter of the way down from the center of the frame.

We weld tubes vertically to the back of the frame for mounting the axle. The moving parts will be installed there later.

Using an electric drill, drill centimeter-sized holes in a location convenient for fastening.

Step 3. Making vertical posts

We weld a post, leaving at least 5 centimeters from the edge of the base. The square profile is up to 50 centimeters long. We then weld a second post, smaller than the previous one, no longer than 40 centimeters, measuring 40 centimeters. The next post is measured at 30 centimeters, and the next profile is also welded in place. The finished product resembles a pair of stairs.

The posts are secured in the lowest section of the unit with a metal strip. We use a strip no thicker than 0.5 mm and weld the profiles together at a 45-degree angle.

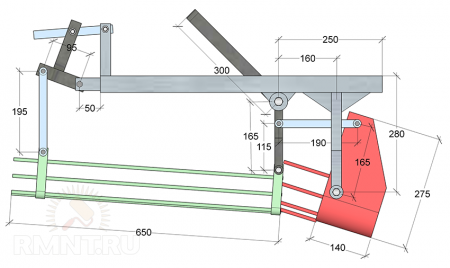

Step 4. Create a ploughshare and a plowshare

Having constructed the main part of the homemade potato digger, we move on to the production of the active part of our digger, the ploughshare, which will perform the main part of the work of harvesting potatoes.

To create a ploughshare, a blade that will cut the soil, we'll need a metal plate at least 0.3 mm thick. Using a pre-selected design, we cut two blades from the plate, the main working parts. The blades are welded together and secured with a special rod. Now we need to give the blade its fullest shape, making it easier to dig and grab the soil. To do this, we tap the center of the blade with a hammer.

Step 5. Making a sloping board

The shovel, or simply steel rods, are a necessary part of the potato digger's working section. They are attached to the ploughshare by welding to the base of the blade.

For making a sloping board, steel rods with a diameter of 10 millimeters and a length of 1.2 meters are best. The reinforcement should be welded to the base of the ploughshare at intervals of 4 or 5 centimeters.

Step 6. Adjustment rods

This element is not always present in the design. It is only necessary if the potential cultivated soil is very waterlogged. They adjust the slope of the slope board.

The easiest way to make adjustment rods for a potato digger for a walk-behind tractor — we make a movable frame on which the reinforcement board will be located.

Step 6. Install the support wheels

The potato digging attachment is completed with support wheels. The design of potato diggers always includes movable elements for easier movement across the surface of the plot.

The best option is wheels from a regular garden wheelbarrow. It's important to use wheels with wide tires.

We've already made and secured the axles to the frame. Now we need to secure the wheels to the axles with a pin, using the same principle as on a wheelbarrow.

Making a simple potato digger

If the vibrating digger option is too complex and labor-intensive for you, you can turn to creating a simpler design for a manual potato digger.

Making a simple potato digger for a mini tractor or a walk-behind tractor does not require special materials or even drawings.

To make a fan-shaped potato digger with your own hands A bipod, which can easily be cut from, say, a shovel, will come in handy. Disused villas can be used as rods.

Further principle of creating a manual potato digger similar to the process of creating a vibration. There are many tutorials on how to create DIY diggers with videos available online.

Potato digger reviews

This device, which significantly simplifies the work of amateur farmers, has resonated with many people. The internet is full of reviews of the potato digger for a walk-behind tractor. or a tractor. Moreover, reviews are left about both purchased devices and homemade potato diggers for walk-behind tractors and mini tractors.

For example, gardeners who have discovered the cultivation of various crops note that such units are a real find.

"A few years ago, I bought a Neva walk-behind tractor and a KVM-3 potato digger for it. This vibrating device made harvesting a joy. I have back problems, so I can't use a shovel. But after working with the potato digger, my sore back feels completely pain-free."

As you can see, the use of a potato digger for a walk-behind tractor Significantly reduces the need for physical labor. This is an important factor for gardeners, many of whom are elderly and have health issues. Even those without health issues appreciate potato diggers for mini tractors or walk-behind tractors. Active labor, which is already abundant on the land, can lead to deterioration in health, even if it was previously perfect. Therefore, using potato diggers is a form of preventative health care during harvesting. Especially a potato digger for a walk-behind tractor. It can be used for other purposes, it is great for harvesting various crops, not just potatoes.

"I'm very happy with my potato digger purchase. It's incredibly convenient and efficient to use. It's easy to learn how to use. Simply attach the unit to your walk-behind tractor and move around your plot. Meanwhile, the unit does all the work for you. I was able to harvest all the potatoes in my plot in two days. Instead, it would have taken me at least a week to shovel."

From this review it becomes clear that potato tractor diggers and others not only conserve health but also another valuable resource: time. The speed of harvesting can depend on various factors. Not everyone can afford to spend weeks harvesting all their potatoes. However, a potato digger can speed up the process significantly. This is especially important for those planting large quantities of potatoes.

https://youtu.be/6jG38IsOWEU

"Every penny I spent on my potato digger was worth it. I basically didn't dig potatoes this year; I managed 30 acres in a weekend, and no one hurt their hands."

Even if the potato digger is for a walk-behind tractor Although it was purchased for a considerable sum, consumer experience shows that the money was well spent. Besides saving time and health, the potato digger for the walk-behind tractor It also provides material savings. For example, gardeners don't need to take vacations or time off to harvest everything from their plots. The device also improves harvest quality, which can increase the final yield. Finally, by harvesting all the potatoes from the plot before frost, rain, or other unfavorable circumstances, the farmer will only benefit. Knowing how to make a potato digger yourself can save even more.

Today, there's a wealth of information online about all types of gardening equipment. You can even find video instructions for building or repairing a potato digger for a walk-behind tractor.. You can find a detailed description of how to make a potato digger for a walk-behind tractor, information on proper use, repair or replacement options, and other relevant information. Using global experience from open internet sources, you can make Almost anyone can make a potato digger for a walk-behind tractor. All it takes is time and some basic welding, drilling, grinding, and other skills.

How to choose a saw for your garden: everything every gardener needs to know

How to choose a saw for your garden: everything every gardener needs to know Robotic Lawn Mowers: Should You Trust Your Grass to These Automatic Helpers?

Robotic Lawn Mowers: Should You Trust Your Grass to These Automatic Helpers? Which garden hose is best? All the aspects to consider

Which garden hose is best? All the aspects to consider Electric vs. Gasoline Trimmers: Which One to Choose for Your Yard?

Electric vs. Gasoline Trimmers: Which One to Choose for Your Yard?