In this article, we'll discuss how to build a DIY greenhouse using polycarbonate and plastic pipes. Polymers have long since replaced wood, glass, and even metal as greenhouse materials. In garden plots, it's quite common to find plastic pipes used to make special greenhouse frames. The advantages of this material are obvious, even at first glance: mold doesn't grow on them, and vapors don't warp the pipes, nor do caustic chemicals or moisture.

In this article, we'll discuss how to build a DIY greenhouse using polycarbonate and plastic pipes. Polymers have long since replaced wood, glass, and even metal as greenhouse materials. In garden plots, it's quite common to find plastic pipes used to make special greenhouse frames. The advantages of this material are obvious, even at first glance: mold doesn't grow on them, and vapors don't warp the pipes, nor do caustic chemicals or moisture.

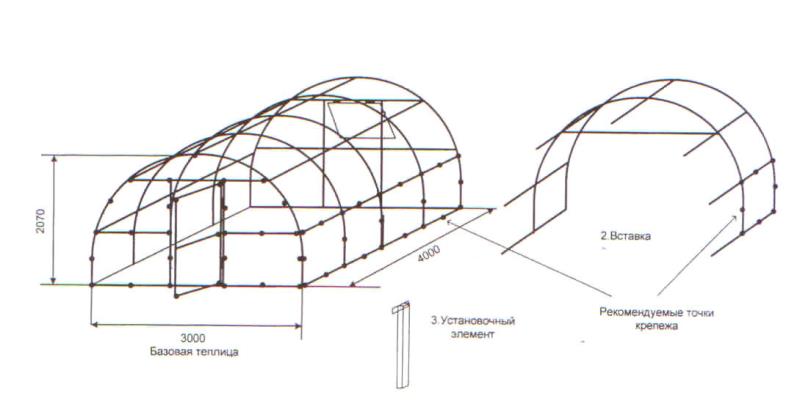

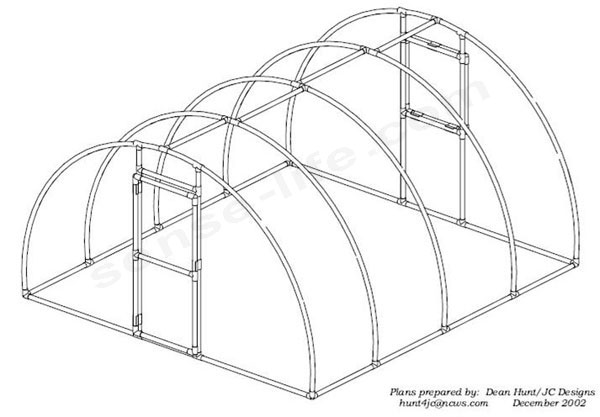

To minimize financial costs and create a durable greenhouse for your garden, you can do it yourself. This article features clear, easy-to-understand photos, diagrams, videos, and excellent advice from professionals on how to build a DIY greenhouse from polycarbonate and plastic pipes.

Interesting! When building a greenhouse yourself, plastic pipes for the frame offer many advantages. They are easy to cut and bend, and they can be glued without any problems.

What types of pipes should be used to build a greenhouse?

- Rigid PVC pipes are not known for their flexibility. However, they are ideal for building gable and lean-to greenhouses with clean, straight lines and edges. These types of greenhouses were once the most common on property plots; they are quick to construct and don't require complex plans, yet they perform their basic functions perfectly.

- Flexible polypropylene or PVC pipes are also available. These types of pipes are ideal for constructing an arched structure or a rounded roof over a rigid frame.

- Initially, the frame is necessarily made of solid pipes, and then an arched structure is created on top using a more flexible, but still strong material.

- It's worth noting that, regardless of the type of polymer pipe, all are manufactured with fittings—these include cross-connectors and special swivel joints, as well as adapters and special parts for joining pipes of different diameters. Don't skimp on fittings, as they will speed up construction and simplify installation.

- It's important to consider whether the greenhouse will be permanently installed or whether it should be designed to be portable. In the first case, the parts can be glued together permanently, while in the second case, screws are essential.

Stages of greenhouse construction

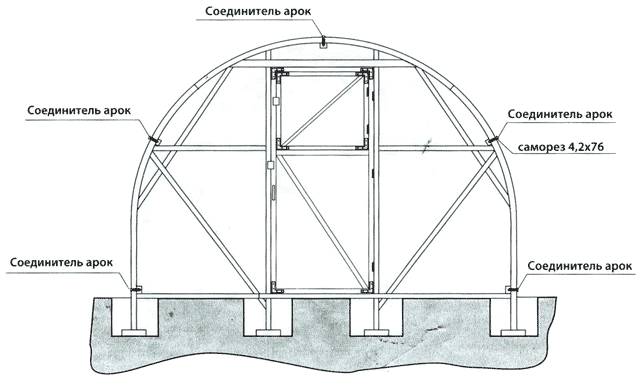

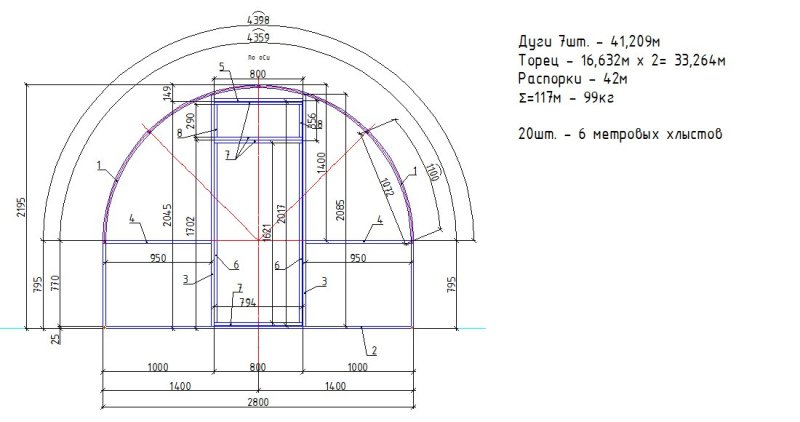

Regardless of the chosen design, the construction process for this type of greenhouse will consist of a number of fairly well-defined steps. First, you'll need to build a foundation; this serves as a foundation, which is a plus. Pouring concrete or supporting pillars is laborious and expensive. However, for a lightweight structure made of plastic pipes, simply building a good foundation will suffice.

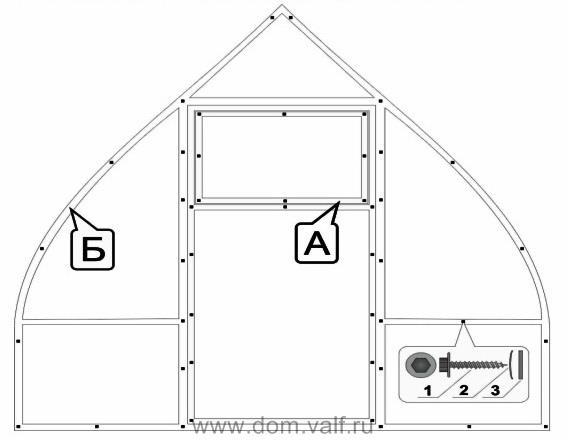

Next, you'll need to create a frame. Depending on the chosen design, you'll need to use either rigid polymer pipes or flexible polymer pipes in addition. Different materials are used for fastening, depending on whether the greenhouse is portable or permanent. Film is most often used as the top covering, but polycarbonate is now readily available and has excellent performance properties, making it suitable for this type of greenhouse. Glass, however, is strictly prohibited due to its weight.

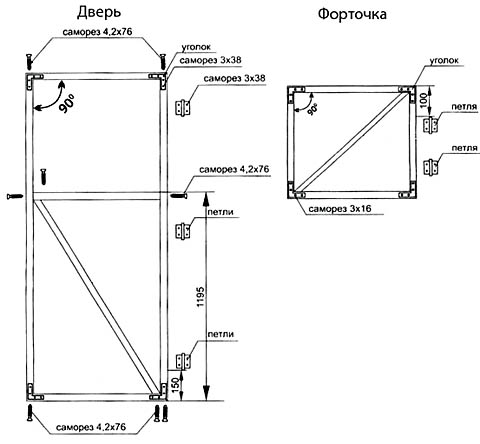

After the frame is in place, the end pieces need to be constructed to house the ventilation vents and doors. Then the transom, casements, doors, and locks are hung. Greenhouse made of metal profile pipes with your own hands.

Creating a base for the frame

Before building the greenhouse itself, you'll need to decide on its foundation. This is the frame, which is essential for supporting the lightweight structure. Furthermore, the frame helps the structure maintain its airtightness, which is crucial for a successful greenhouse and a good harvest. The choice of foundation doesn't depend on the specific design of the future structure, and this is another important advantage. Here, you'll likely need to consider the structural integrity of the structure and the available funds.

To make the frame of a plastic greenhouse, you can use a board as the base. It should be about 6-8 mm thick. A 6x12 or 8x12 beam can be used as the base. Rigid plastic pipe is also suitable, but it should only be used as a bottom rail.

Plastic pipes, regardless of their rigidity, are lightweight, meaning the greenhouse will also be lightweight. Therefore, a thick lumber frame is essential for the plastic frame, which will increase the load-bearing capacity and make it strong and reliable. The base of the timber is further buried in the ground, requiring a trench to be dug. Roofing felt should be laid in the trench, the bottom and sides of the trench should be sealed, and then the prefabricated wooden frames can be installed.

All the projects described above can be used in conjunction with any plastic greenhouse design. It's important to consider the location of the structure from the outset and then select the optimal foundation accordingly. How to build greenhouse made of polypropylene pipes with your own hands.