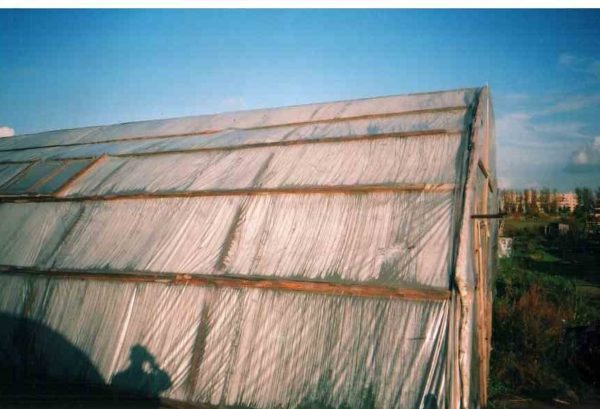

To save space in your garden and avoid spending a lot of money on greenhouse construction, one excellent option is a cost-effective and easy-to-install stretch film structure.

It's lightweight and easy to transport and move around. It's especially suitable for small garden plots where installing multiple greenhouses isn't feasible.

Advantages and disadvantages

This type of film was not previously used as a covering material for greenhouse structures. However, it is now popular among gardeners and horticulturists. It has several advantages.

This type of film was not previously used as a covering material for greenhouse structures. However, it is now popular among gardeners and horticulturists. It has several advantages.

- Serves for two to three years.

- Not subject to spoilage.

- Good thermal insulation properties. Helps maintain air humidity necessary for plant growth.

- No additional equipment or fasteners are required for installation.

Once fully installed, it's clear there's no difference from other types of structures. Structures made from it are lightweight. When wrapped, an air space is created between the layers. This helps retain heat inside the room and helps neutralize the harmful effects of sunlight. It allows ultraviolet rays to pass through, which ultimately allows plants to mature faster.

When building with stretch material, it's possible to avoid the need for additional fasteners. It's quite flexible. It can be used to create any structure without damaging it due to its light weight. Construction of such structures is very quick.

What are the negative properties?

- Because the air in a room with such covering material heats up instantly, plants do not tolerate heat or direct sunlight well.

- It is difficult to install sashes and vents using stretch film.

- Structures with this covering material quickly lose their original beauty.

- Stretch gets dirty quickly, so it needs to be washed regularly.

Foundation for a greenhouse

To build greenhouse There's no need to build a foundation using stretch film. For example, if you're using wood for the frame, a simple foundation of ceramic bricks or wooden beams will be required to fully strengthen the structure. If you're using a polypropylene pipe frame, good soil compaction will suffice.

For structures over one and a half meters in height, it is best to use additional frame fastening to prevent gusts of wind from blowing your greenhouse away.

Greenhouse frame material

The foundation is crucial. It determines the stability of the entire structure and its resistance to adverse weather conditions. Therefore, it follows that the weather is taken into account when choosing the building material for the frame.

The foundation is crucial. It determines the stability of the entire structure and its resistance to adverse weather conditions. Therefore, it follows that the weather is taken into account when choosing the building material for the frame.

- Wooden frame. This building material is often used in construction. The cost is significantly lower. However, it requires constant maintenance and additional treatment against insects and rot.

- The frame is made of metal and steel. These materials provide reliability and durability. It lasts for several years. Simply paint and treat the posts with anti-corrosion compounds.

- The frame is made of aluminum. It's lightweight and more durable than the first two materials. It requires no additional maintenance; preventative measures are sufficient.

Selecting stretch film

The key factors in choosing the right stretch film are thickness and resistance to external factors. The table below presents the key parameters by which to compare different types:

| Film type | Thickness | Resistance to external factors |

| Kling | 5-11 µm | Low, easily torn |

| PVC | 20-30 microns | Medium, tears with effort, but lets heat through |

| EVA | 13-20 microns | High, has better thermal insulation properties |

| Made of polystyrene | 7-18 µm | Medium, tears with effort, but has less elasticity |

As It is better to choose covering material PVC. As the table shows, cling film is thin. Covering a greenhouse frame with it will require 7-8 layers.

To avoid mistakes when working with it, it's important to pay attention to the type of material. For example, polystyrene doesn't stretch well, unlike PVC, which can stretch three to four times its original size without losing its properties.

Selecting a design

The best design is an arched greenhouse. It is assembled using vertical support elements. Its height can vary greatly, and the thickness is selected individually. This type of greenhouse does not require additional foundation and roof construction. A damaged element can be replaced individually.

The best design is an arched greenhouse. It is assembled using vertical support elements. Its height can vary greatly, and the thickness is selected individually. This type of greenhouse does not require additional foundation and roof construction. A damaged element can be replaced individually.

Also, don't forget about the weather in your region. Consider the snow level during the winter. The arched design will help prevent excessive stress on both the foundation and the covering material itself.

You may be interested in:

You may be interested in:Calculations

In order to correctly determine the amount of building materials required to construct a greenhouse from stretch film, it is necessary to take into account its basic parameters.

- What vegetable crops will be grown in the greenhouse? Its height should be approximately one and a half times greater than the height of the plants.

- The number of support elements depends on the length of the greenhouse. For example, one support is required for every 2-3 meters.

- Presence of a foundation. If you're not installing a bottom greenhouse frame or building a greenhouse, the support should be 50-60 centimeters longer. This is necessary to allow for proper penetration into the ground.

- A two-layer covering of the frame elements is ideal. After fully calculating the area, add 1/3, as this is used for the overlap, and double the resulting value. To protect plants from wind and drafts, use a "skirt," which accounts for approximately 15% of the resulting length. Then divide the resulting value by two to account for the stretch of the film material.

Assembling the greenhouse

Installation of a stretch film greenhouse begins with the frame. If polypropylene arches are chosen as the building material, they are first dug into the compacted soil. If necessary, the frame must be braced from below. Wooden beams are laid around the perimeter and secured to the vertical supports using clamps and brackets.

Installation of a stretch film greenhouse begins with the frame. If polypropylene arches are chosen as the building material, they are first dug into the compacted soil. If necessary, the frame must be braced from below. Wooden beams are laid around the perimeter and secured to the vertical supports using clamps and brackets.

Metal and wood frames are typically assembled in reverse order. In other words, the end walls are assembled, followed by the lower frame, then the vertical supports, and finally the upper frame.

To wrap a finished frame, there's no need to disassemble or remove it. Wrapping should begin with the upper parts of the structure.

The most difficult parts to assemble are the door and the transom. To do this, use a construction stapler to attach the stretch film to the frame. Next, attach the doors using a glazing bead, ensuring all layers of the stretch film are in place. The same process is done with the transom.

Tips and Mistakes

To build a fully functional greenhouse, there are certain tips that will help you avoid mistakes when installing greenhouses using stretch film.

- This type of film can be attached to various surfaces.

- Before stretching the film, check the frame for strength.

- Avoid any unevenness or burrs in the material used to construct the greenhouse frame.

- Before covering the frame with film, treat it with sanding equipment.

- Do not leave greenhouse elements with only one layer of film.

- Please note that stretch film is prone to destruction when exposed to sunlight.

- Greenhouse height and wind exposure. For greenhouses over one and a half meters tall, additional reinforcement in the form of diagonal bracing is required. This will minimize wind exposure.

You may be interested in:

You may be interested in:Assembling a greenhouse using stretch film as a covering material is easy. Simply follow the instructions and avoid making mistakes. These greenhouses have proven themselves popular among summer residents and gardeners. They save not only money but also time. Maintaining the correct temperature and humidity conditions positively impacts the growth of crops. As a result, they will reward you with an excellent harvest at the end of the season.