Large commodity producers prefer to install greenhouse structures on their private plots as separate structures. On smaller plots, it's not always possible to allocate additional space for construction. A rational solution is to use the framework of existing structures. Supporting a building is a cost-effective way to construct structures for commercial purposes. A wall-mounted greenhouse can not only effectively organize the working space in the garden but also enhance its appearance.

Greenhouse with a wooden frame

A simple way to build a greenhouse next to a wall is to build a frame from planks or beams and cover it with covering material. However, a wooden structure is temporary and won't last many seasons. Tools needed include a screwdriver, a handsaw or circular saw, a plane, a hammer, an axe, and a tape measure.

A simple way to build a greenhouse next to a wall is to build a frame from planks or beams and cover it with covering material. However, a wooden structure is temporary and won't last many seasons. Tools needed include a screwdriver, a handsaw or circular saw, a plane, a hammer, an axe, and a tape measure.

Materials needed:

- wooden beam;

- covering material;

- nails or screws;

- coating for protecting wood from rot and insects.

The amount of materials depends on the dimensions of the building.

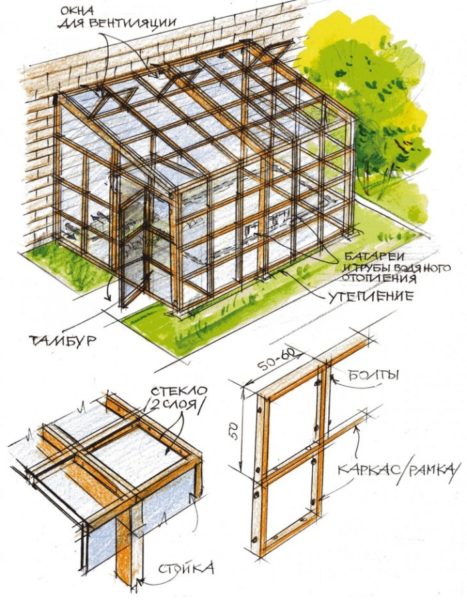

First, choose a location. A well-lit wall, preferably on the south side, is an excellent choice. It should be dry and covered with perennial climbing plants. These can quickly overgrow the structure, reducing sunlight reaching the crops. Once the installation site is determined, mark the outline of the future greenhouse using wooden stakes with twine stretched across them.

To do this, dig a pit half a meter larger than the building's dimensions. The pit's depth is 0.5-0.6 meters. Its edges are lined with straw or peat. The walls are reinforced with boards, plywood, or flat slate. A drainage layer of fine gravel and sand is poured into the bottom of the pit and compacted thoroughly. A fertile soil layer up to 30 cm thick is placed on top.

You may be interested in:

You may be interested in:Once the preparatory work is complete, the frame can be erected. It is assembled from beams using nails or screws. Installation procedure:

- A wooden frame is placed at the bottom of the pit to support the structure. It is made from 100 x 100 mm lumber. Corner joints are made using half-lap or dowel joints. They are secured together with pins or staples.

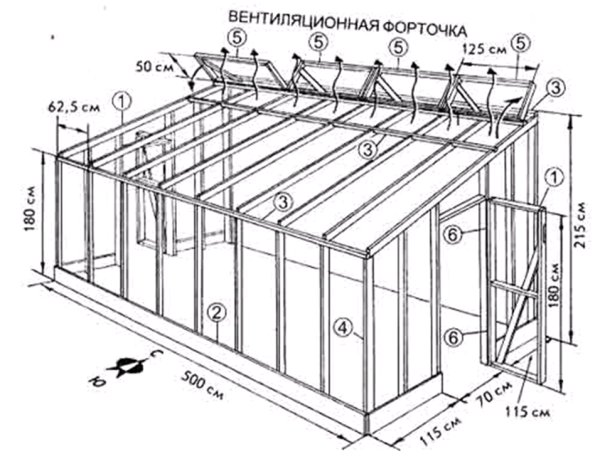

- The side and front walls are assembled. The bottom section (bed), door frame, and ceiling beam are made from 50 x 100 mm lumber. The remaining lumber elements are 50 x 50 mm. A doorway on one side is sufficient.

- A sloping roof is constructed using 50 x 50 mm timber. The spacing between the crossbars should not exceed 60 cm.

- The door panel and vents are assembled from 40 x 100 mm timber. The vents are placed either on the slope or on the front wall. The uprights are joined to the crossbars using a mitered joint.

- The side walls are secured to the frame with nails and to the house with anchor bolts. The front panel is nailed to them, and then the sloped roof is laid on top of them. The elements are connected together with nails.

- The door and vents are installed and the frame is covered with deep penetration antiseptics.

- Cover with insulating material.

Greenhouse with a metal frame

A structure made of square steel tubing is highly durable and long-lasting. The placement of the structure, site markings, topsoil formation, and drainage are no different than with a wooden frame. However, the increased weight requires the greenhouse to be installed on a concrete foundation.

Sequence of foundation construction:

- Dig a trench around the perimeter of the future greenhouse. The hole is 35-40 cm wide and 50 cm deep.

- The formwork is assembled from boards, plywood, chipboard or OSB.

- Place a metal mesh in the trench or tie pieces of reinforcement together.

- They pour concrete and let it dry for a week.

You may be interested in:

You may be interested in:To build a metal frame, you'll need a welding machine, a hammer drill, a screwdriver, an angle grinder, and a tape measure. Necessary materials:

- steel square section profile pipe 40 x 40 x 3 mm;

- cellular polycarbonate 8-12 mm thick;

- door hinges;

- fasteners for polycarbonate;

- paint or primer;

- welding electrodes.

The frame is assembled directly on site. Construction begins at the house wall:

- The pipes are secured using anchors or welding.

- Assemble the base. Lay out the pieces on the foundation and secure them together.

- Vertical posts are installed. Ceiling beams are laid on them.

- The frame is reinforced with lintels and door and window openings are formed.

- Assembling the roof slope.

- They make doors and windows and hang them.

- They check the frame dimensions and the smooth opening of the moving components.

- All joints are welded, cleaned of rust and scale, and painted.

After welding is complete, polycarbonate installation begins. The sheets are cut to length with a 1-2 cm allowance and adjusted to the installation site. Self-tapping screws with thermal washers are used for fastening to steel structures. Fasteners are placed 2-3 cm from the edge. The sheet ends and joints are sealed with a water-repellent material.

Building a greenhouse next to a house wall is interesting because it's easy to assemble. The main load is transferred to a sturdy support, which reduces material costs.