When planting garden crops in early spring, gardeners face significant risks. Spring frosts always accompany early planting. Vegetables and greens require protection and warmth to thrive. Compact polycarbonate greenhouses (CPC) provide this protection. All models have opening tops and are easy to assemble and install in your garden. Growing vegetables in greenhouses is the key to protecting them from the cold and ensuring a good harvest.

What are greenhouses made of polystyrene and their purpose?

Greenhouses These greenhouses are designed for growing small seedlings indoors. Cellular polycarbonate is a transparent and durable material. It allows sunlight to pass through well. The sun penetrates the cellular structure of the polycarbonate, warming the seedlings and soil. The greenhouse retains heat for a long time, and the temperature inside remains stable. Fertilizing the beds with decomposing organic matter releases carbon dioxide into the atmosphere.

It's important to understand the differences between hotbeds and greenhouses. A hotbed is smaller than a greenhouse, measuring no larger than a person's height. Hotbeds do not require heating or automatic irrigation systems. These structures can be used to grow:

- flowers;

- greens (onions, garlic, sorrel, parsley, salads);

- berries (strawberries, wild strawberries);

- small vegetables (beets, carrots, cucumbers, tomatoes).

Greenhouses are not designed for growing large crops. Each model ranges from 1.5 to 4 meters in length, 1 to 3 meters in width, and 1 to 1.5 meters in height.

The greenhouse gradually accumulates heat. When it gets hot outside, this can lead to overheating and plant death. In hot weather, always open the greenhouse's doors to ventilate the seedlings.

Advantages of the design

Greenhouses made of cellular polycarbonate have clear advantages over hothouses. A hothouse is a large and bulky structure. Its installation requires a large plot of land, whereas a hothouse can be erected on any small plot of land. Greenhouse designs are distinguished by their simplicity. Some models are sold ready-made—all that remains is to assemble them correctly and install them in the ground. These ready-made models are inexpensive due to their simplicity and low material consumption.

A greenhouse made of polystyrene composite is durable and can withstand rain and wind. At the same time, it's lightweight and can be moved anywhere at any time. If a gardener doesn't like prefabricated models, they can build one themselves using materials of their choice. Folding lids are a unique invention, making it easy to water and weed plants.

Polyethylene greenhouses are common in gardens, but cellular polycarbonate lasts longer. It's stronger than glass and can even withstand mechanical damage. Polycarbonate has higher impact strength than glass, making these structures increasingly common in garden plots.

Selecting a location for installation

Choosing a location isn't a problem when it comes to installing a greenhouse on a small garden plot. Space is limited and options are limited. A larger plot is a different matter. With a large plot, installing a greenhouse requires careful consideration, choosing a location that's most suitable for growing crops. There are certain conditions that must always be met:

- Greenhouses are placed on the south or east side. This will provide the plants with sunlight. The structure should not be placed on the west or north side.

- the structure should not be located in the shadow of a fence, trees or a house;

- It's important to provide protection from the wind. It's best to place a fence or other building a few meters away from the greenhouse.

The structure must not be installed in a low-lying area or a swampy location. If the site is located in such a location, it must first be reinforced with embankments and drainage work must be carried out.

Construction of the foundation

Greenhouses made from polystyrene composites are lightweight and portable structures. They don't require a strong foundation, but if they are planned for long-term use, a suitable foundation is necessary. The following materials are used for the foundation:

- timber;

- concrete;

- brick.

The foundation serves as thermal insulation. It prevents the ground from freezing during the cold season. The base retains the heat generated by the decomposition of organic matter in the beds within the greenhouse. Construction begins with marking the ground along the perimeter of the future structure. After marking, dig a trench 10-25 cm deep and fill it one-third with sand. A wooden frame made of lumber is placed on top. If you have red brick, you can use it instead of the lumber frame.

There will be a space between the masonry and the walls of the hole. This space is filled with soil or gravel. The foundation and greenhouse are secured to the ground with long metal pins, driven into the ground to a depth of 50-70 cm. This depth will ensure the lightweight structure is stable and will not be blown away by a strong gust of wind.

There will be a space between the masonry and the walls of the hole. This space is filled with soil or gravel. The foundation and greenhouse are secured to the ground with long metal pins, driven into the ground to a depth of 50-70 cm. This depth will ensure the lightweight structure is stable and will not be blown away by a strong gust of wind.

Types of greenhouses and their assembly

There are three types of greenhouses with an opening top:

- A bread bin is an arched structure with one or two doors. They can be raised and slid open just like the doors of a regular bread bin;

- butterfly - greenhouse with an arched cross-section. It has two flaps that are raised upward, like the wings of a butterfly or a bird;

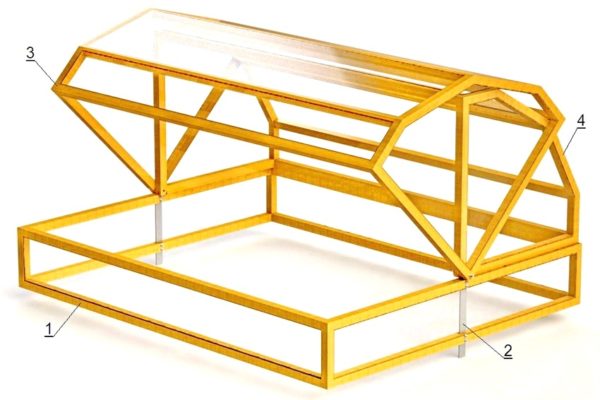

- The Belgian model has a pitched or gable roof. The roof is also raised, and the greenhouse resembles a box or chest.

The type of greenhouse should be chosen based on the size of the plot and the location of other structures on it. Assembly instructions vary for each type, but installation doesn't take much time.

Instructions for assembling a breadbox greenhouse

Bread bins can have two or one door. They slide open, and the moving parts are secured with a simple hinge mechanism. The cellular polycarbonate sheets used for the frame are 4 mm thick. The frame is made of 20x20 mm metal profiles. Wooden frames are not used for bread bins, as wood cannot be shaped into an arch or bent in the desired direction.

First, the site is prepared for the greenhouse by clearing it of weeds and debris. If necessary, a foundation is installed. Once the foundation is in place, the metal frame is assembled. The frame is covered with sheets of polystyrene foam, joining one sheet to the next, and then installed on the site. There's a company called "Innovatsiya" that makes convenient and practical "bread bins." They can be installed even in the smallest of plots.

The assembly instructions for such a greenhouse are provided as an example:

- The ends of the structure are unpacked and removed separately. These are arches with vertical posts located in the center. The posts are designed to stabilize the greenhouse;

- The SPK sheets are removed from their packaging. It's important to determine which side has the protective coating;

- Place one sheet of SPK on its end and secure it to the metal profile with roofing dowels. It's best to use thermal washers instead of screws. This will prevent the material from warping and swelling under high temperatures.

- The end of the sheet is cut along the perimeter. Use a utility knife for this job;

- the second end of the greenhouse is assembled in the same way as the first;

- the frame is assembled by connecting horizontal ties to the ends;

- They begin assembling the sash. It is longer than the frame, with ends reinforced with braces;

- a sheet of polycarbonate is placed on the sash and fixed with self-tapping screws;

- the lid is installed on the frame base and its operation is checked;

- a handle is attached to the lid.

You may be interested in:

You may be interested in:When joining polycarbonate sheets, use perforated sealant tape. Polycarbonate is a cellular material, so it must be protected from dirt and moisture penetration. A small gap must be left between the hinged lid and the metal frame to allow free airflow into the room.

The interior of the frame also needs to be protected from moisture penetration to prevent the metal from rusting from the inside. For this purpose, plastic plugs are used to seal the ends of the metal profiles. Attachment points and areas with damaged coating are treated with cold zinc. These measures contribute to the long life of the structure.

The interior space can be arranged by creating heated beds. Before installing the greenhouse, dig a hole 50-60 cm deep. Fill the hole with organic matter. Place several thick branches or corn leaves at the bottom. Place small leaves, shrub remains, and wood shavings of any size on top of the larger branches. Fill the hole with a 15-25 cm layer of soft, nutritious soil. Pre-water the organic matter with an effective microbiologically-based solution. This solution promotes rapid decomposition. The decomposing matter will continuously warm the bed from the inside, providing the plants with the nutrients they need for growth and development.

Butterfly greenhouse assembly instructions

The butterfly's top can be opened on both sides. Raised flaps allow fresh air to flow when ventilating the plants and provide access for maintenance. Assemble the butterfly as follows:

- prepare the site, clearing it of debris and weeds;

- lay the foundation if necessary;

- remove the packaging from the SPK sheets and frame;

- on the SPK sheets, they determine where the protective coating from ultraviolet radiation is located;

- Both ends are assembled. They look like arches on vertical posts;

- Assemble the hinged lids. Rounded parts and clamps are used during assembly. The clamps are installed horizontally;

- the ends are connected to the coupler with bolts or a welding machine;

- The lids are attached to the frame with hinges. Each lid should have two hinges;

- Fixing posts are added to the lids. These will hold them open when ventilating the greenhouse;

- check whether the fasteners are securely connected;

- The sheets of SPK are successively applied to the ends of the building and fixed with dowels or thermal washers, carefully trimming along the edges;

- After both ends are installed, the SPK sheets are placed on the frame and hinged lids. A small overhang, 5 to 8 cm long, should form along the edges;

- the sheets are fixed to the frame base and covers with self-tapping screws;

- the casing of the folding posts is cut with a construction knife;

- check the operation of the system;

- attach handles to the hinged lids;

- install the assembled greenhouse into the ground using a building level.

To seal the ends, use sealant tape at the top and perforated tape at the bottom.

Assembly instructions for a Belgian greenhouse

The Belgian greenhouse is a simple model. It doesn't have round or curved elements like butterfly boxes and bread bins. The homemade box is assembled from wood or metal profiles. The assembly instructions are as follows:

- A simple drawing of the future structure is made. It indicates the length, height, and width of the frame and the greenhouse as a whole;

- clear the area of debris and weeds and build a foundation, if necessary;

- cut the metal profile or timber into pieces of the required length;

- Assemble the frame base. Metal corners can be used during assembly. The metal profile pipe is secured with nuts and bolts, and the timber is secured with dowels and metal corners.

- the posts are attached to the frame, positioning them vertically;

- the rafters are placed between the posts;

- assemble the lid;

- they put it on the loops and fix it to the base;

- install holders: they will support the lid during ventilation;

- They begin covering the base with polycarbonate. They remove it from its packaging and determine where the protective layer is located;

- The sheets are applied to the ends, secured to the frame with screws, and trimmed. This covers all the walls;

- cover the lid with polycarbonate, attach it to the frame base and cut it;

- install the structure on a foundation or in the ground.

Reviews

Marina (Kostroma):

"We have a small garden plot, just 600 square meters. Space is limited, so a large greenhouse definitely won't fit. We chose the breadbox model. It's compact, durable, and easy to use. I appreciate the retractable doors, which slide open with a gentle movement. The doors don't take up any space, and when fully opened, they provide access to the seedlings. We bought our greenhouse at the store, disassembled. At first, we were worried we wouldn't be able to assemble it ourselves, but we quickly took it apart and set it up in a day. It's on the south side, where it gets plenty of sun. For the second year in a row, we've been growing herbs, cucumbers, and tomatoes in it. For the winter, we carefully disassemble the structure and store it in the shed, then reassemble it in the spring."

Yuri (Moscow region):

"I made a simple and convenient Belgian box myself. I didn't bother with metal pipes or complicated greenhouse designs. I took some sturdy timber, made a frame for the box, and bought sheets of cellular polycarbonate at the store. Assembly wasn't difficult; the main thing was finding the hinges and the lid clamp. When unpacking the polycarbonate, it's important to understand which side has the protective coating. During work, the sheets should be secured so that the coating faces the outside. The result is a small greenhouse for greenery and flowers."

Valery (Saratov):

"We live in a large country house. Initially, we considered building a full-fledged glass greenhouse on our property. After calculating the costs, we decided it was out of our budget. We'd need to install electrical wiring and an irrigation system. It's both time-consuming and expensive, so we decided to go with a hotbed. We liked the butterfly greenhouse because it offers a large space for growing a variety of vegetables and plants. They're always accessible from both sides, and if it gets hot outside, we open both doors to ventilate the seedlings. While a hotbed can't compare to a full-fledged greenhouse, the butterfly greenhouse has become a good alternative for us."

You may be interested in:

You may be interested in:A hothouse isn't a greenhouse, but it can be a worthy option for growing garden crops. A simple model can be assembled by hand or purchased in a store and quickly installed on your property. Cellular polycarbonate is easy to work with; the key is to do everything carefully to ensure long-lasting durability.