To extend the growing season of heat-loving plants and obtain an earlier harvest, greenhouses are installed in garden plots in the northern regions of the country. Using solar energy and decomposing biofuel (manure), they smooth out daily temperature fluctuations and protect plants from sudden frosts. Many greenhouse options are available commercially, but building your own requires little time and effort, and the cost is several times lower.

How a greenhouse is constructed

Structurally, a hotbed differs from a greenhouse only in size. A hotbed can be several dozen meters long, and its width is chosen to allow for easy plant care from both sides. The height of the structure is determined by the size of the plants to be grown within it. For early greenery, the height is 30-40 cm, while to protect cucumbers from the cold August dew, the height is 1.5-2 meters.

Structurally, a hotbed differs from a greenhouse only in size. A hotbed can be several dozen meters long, and its width is chosen to allow for easy plant care from both sides. The height of the structure is determined by the size of the plants to be grown within it. For early greenery, the height is 30-40 cm, while to protect cucumbers from the cold August dew, the height is 1.5-2 meters.

Based on their design, all greenhouses can be divided into two groups:

- Horizontal. In this case, a small frame is installed on the garden bed, covered with glass frames, polycarbonate, or film. This structure is windproof and retains heat well. Its drawback is the low height of the plants grown.

- Vertical or arched. These greenhouses are constructed by attaching arches or arcs to the base, which are then covered with film or cellular polycarbonate. Arched greenhouses can be installed at any desired length and moved to the desired bed if needed. They can accommodate plants of any height. A disadvantage of this design is low wind resistance and lower temperatures inside the shelter.

Pros and cons of homemade designs

Homemade greenhouses have their advantages and disadvantages.

Homemade greenhouses have their advantages and disadvantages.

Advantages of homemade greenhouses:

- the cost of self-made structures is much lower than that of purchased options;

- greenhouses do not require financial costs for heating;

- greenhouses can be easily disassembled for winter storage in a dry place, thereby increasing the service life of the structure several times;

- lightweight arched structures can be moved from one place to another several times, placing them in the location needed at the moment;

- Homemade structures can be made from almost any materials available to the craftsman;

- Lightweight arc shelters can be of virtually unlimited length;

- Only by making it yourself can a greenhouse fit perfectly into the landscape of the site.

Disadvantages of homemade greenhouses:

- To independently manufacture shelter structures, you will need metalworking and carpentry tools;

- assembly of an industrially manufactured structure will require several times less time;

- tall varieties of tomatoes and peppers do not fit into low greenhouses;

- It is problematic to organize water and electric heating in greenhouses.

Materials and tools for manufacturing

Each type of greenhouse requires its own set of materials. For horizontal shelters, timber, planks, or thin tree trunks are used for the frame. Pickets or timber are used to make the frames.

Each type of greenhouse requires its own set of materials. For horizontal shelters, timber, planks, or thin tree trunks are used for the frame. Pickets or timber are used to make the frames.

Timber or planks are used for the foundation of vertical structures. Arches are made from industrially produced arches, polypropylene or metal pipes, profiles, wooden beams, and slats. For the simplest arch option, fresh willow rods with a diameter of 1.5–2 centimeters are used.

As a covering material Film, cellular polycarbonate, or glass are used. In case of sudden frost, plants inside the greenhouse are additionally wrapped with agrofibre for additional insulation.

Tools required for the job

To make shelter structures yourself, you will need the following set of tools:

To make shelter structures yourself, you will need the following set of tools:

- for marking you will need a carpenter's square, marker, pencil, scriber, tape measure;

- To work with wood you will need a saw, hammer, nails, plane, axe;

- To work with metal you need an angle grinder and a hacksaw;

- To connect the parts you will need a drill/screwdriver, self-tapping screws, construction corners, and drills.

Materials used for greenhouse cladding

Glass, cellular polycarbonate, or film are used to protect plants in greenhouses. Each of these materials has its own niche applications, advantages, and disadvantages.

Glass

Glass is the oldest covering material, used in gardening for hundreds of years. Typically, it is used to cover greenhouses by glazing the frames.

Advantages of glass:

- very high light transmittance;

- glass has the highest durability;

- the glass does not deform when weather conditions change;

- low thermal conductivity of glass walls and frames;

- High chemical resistance. The glass does not cloud when exposed to aggressive fertilizer solutions or pesticides;

- Glass retains its properties for many years. Therefore, pieces of old window glass can be successfully used for glazing greenhouse frames;

- High abrasion resistance. Dirty glass can be easily washed or wiped with a cloth.

Disadvantages of glass:

- high cost;

- the complexity of manufacturing greenhouse frames;

- the difficulty of cutting glass and installing it in a frame.

Film

Film is a very popular and widely used greenhouse covering material due to its affordability and ease of use. It can be used to cover any type of greenhouse.

Film is a very popular and widely used greenhouse covering material due to its affordability and ease of use. It can be used to cover any type of greenhouse.

There are three most common types of film.

- Polyethylene film is the most affordable. It is sold in rolls ranging from 120 to 300 cm wide. Polyethylene film lasts for 1-2 seasons and is very resistant to mechanical damage.

- Polyvinyl chloride film is stronger than polyethylene, retains heat better, and effectively blocks infrared rays. Its service life can reach up to 7 years.

- Reinforced film has the highest strength. It contains tensile-strengthening carcass threads. Reinforced film has a service life of up to 3 years.

Advantages of the film:

- low cost;

- good transparency;

- high plasticity;

- light weight.

Disadvantages of the film:

- Low mechanical resistance. The film wears out quickly where it comes into contact with frame elements;

- Condensation accumulates on the inside of the film at night. Wet film quickly becomes dirty and transmits less sunlight;

- the film gradually deteriorates under the influence of sunlight;

- At sub-zero temperatures the film becomes very brittle.

Cellular polycarbonate

Cellular polycarbonate is a new transparent covering material. Polycarbonate does not tolerate repeated bending well, so it is used in greenhouse construction to cover frames.

Cellular polycarbonate is a new transparent covering material. Polycarbonate does not tolerate repeated bending well, so it is used in greenhouse construction to cover frames.

Advantages of polycarbonate:

- High abrasion resistance. If necessary, any dirt can be washed off with a cloth without damaging the polycarbonate surface;

- the service life of polycarbonate is 5-7 years;

- high transparency of polycarbonate;

- Cellular polycarbonate is very durable. It easily withstands snow loads and hail impacts;

- the material is not destroyed by cold and heat;

- low weight.

Disadvantages of polycarbonate

- Cellular polycarbonate is not suitable for covering arched greenhouses.

Covering material fasteners

https://youtu.be/d40oxPkdUvc

The method of fixing the covering material depends on greenhouse structures and the material itself. Glazing beads are used to secure the glass in the frames, the polycarbonate is screwed to the sheathing with screws, and a furniture stapler or small slats are used to press the film in place.

Several homemade clamps have been invented to secure the covering material to the arches:

- a thick watering hose or PVC pipe is cut into 7-10 cm pieces. The pieces are cut lengthwise and used as clamps;

- Paper clips press the film well against the arcs;

- Clips for plumbing pipes are successfully used to fix the film to the pipes.

The simplest arched tunnel

A simple arched greenhouse is widely used for growing a variety of plants. Because it can be easily assembled and disassembled, the arched tunnel can be moved several times during the season. In the spring, green crops or seedlings are grown under it, using it as a shelter from the cold. In early May, the arches are installed over the newly planted seedlings, providing sun protection. In midsummer, the tunnel is moved to strawberry beds to protect the berries from birds. The arches are covered with plastic (for warmth), agrofibre (for shade), or fishing net (to protect against birds).

A simple arched greenhouse is widely used for growing a variety of plants. Because it can be easily assembled and disassembled, the arched tunnel can be moved several times during the season. In the spring, green crops or seedlings are grown under it, using it as a shelter from the cold. In early May, the arches are installed over the newly planted seedlings, providing sun protection. In midsummer, the tunnel is moved to strawberry beds to protect the berries from birds. The arches are covered with plastic (for warmth), agrofibre (for shade), or fishing net (to protect against birds).

To make an arched tunnel, the following algorithm is used:

- The rods for the arches are cut from 6-8 mm diameter wire. The rod length is calculated using the formula: the ridge width multiplied by 3.14 and divided by 2 plus 30 cm.

- Using a mallet, arches are bent from rods using a template.

- The bed for the future greenhouse is dug up, and arcs are driven into the ground across it at a distance of 40-50 cm.

- The top of the arches is covered with film.

The film is pressed down on the sides and ends with boards or bricks.

Insulated arched greenhouse

An insulated arched greenhouse is used for growing plants of any height. It is permanently installed in the sunniest and most wind-free area of the garden.

An insulated arched greenhouse is used for growing plants of any height. It is permanently installed in the sunniest and most wind-free area of the garden.

The following algorithm is used for its production:

- A box 30 centimeters high is knocked together from boards or timber.

- The arches for a powerful insulated greenhouse are made of metal or plastic water pipes, a square section profile, or smooth metal rebar with a diameter of 10-12 mm. The source material is cut into rods of the required length, then arches are bent using a pipe bender or mallet using a template.

- The arches are installed inside the foundation box, secured to it with plumbing clamps. To provide rigidity, a ridge cap is installed at the top of the arches. A piece of water pipe equal in length to the box is used for the ridge cap. The arches are secured to the ridge cap with plastic ties.

- To stabilize the temperature at night, heat accumulators are buried inside the box around its perimeter. These accumulators are 1.5- or 2-liter plastic bottles filled with water. The water is heated by the sun during the day and transfers heat to the plants at night.

- The ends of the structure are covered with plywood, polycarbonate or boards, attaching them to the arches with self-tapping screws.

- The greenhouse is covered with film from above.

Shelter made from plastic bottles

Clear plastic bottles are a good material for making greenhouses. The plastic they're made from allows sunlight to pass through and retains heat well. To make a shelter from plastic bottles, follow these steps:

Clear plastic bottles are a good material for making greenhouses. The plastic they're made from allows sunlight to pass through and retains heat well. To make a shelter from plastic bottles, follow these steps:

- A box 50-70 cm high is knocked together from timber or thick boards. The length of the box depends on the available material, and the width is 120-140 cm. The box is installed on the ridge, leveling the top.

- Greenhouse frames are constructed from thin slats. The length of the frames is equal to the width of the box, and the width is 80-100 cm.

- Clear 1.5-2 liter soda or beer bottles are cut off at the top and bottom and slit vertically. The resulting cylinder is placed on a flat surface, covered with a cloth, and ironed. After heat treatment, the plastic becomes flat. The resulting sheets are sewn together with wire or thin fishing line to form a fabric.

- Using a furniture stapler, the canvas made from plastic bottles is attached to the frames.

Greenhouse made from window frames

Old window frames are an excellent material for making your own warm greenhouse. Glass retains heat well and allows the full spectrum of solar radiation to pass through. Seedlings thrive very quickly under glass frames.

Old window frames are an excellent material for making your own warm greenhouse. Glass retains heat well and allows the full spectrum of solar radiation to pass through. Seedlings thrive very quickly under glass frames.

Before starting work, recalculate the available quantity window frames and calculate the dimensions of the future structure. From there, everything depends solely on the builder's imagination. If there are a large number of frames, they can be used to create a transparent base box using screws, which is then covered with the remaining frames. If there is only one or two frames, the base is constructed from planks, and the frames are used to cover only the top of the structure.

Cucumber hut

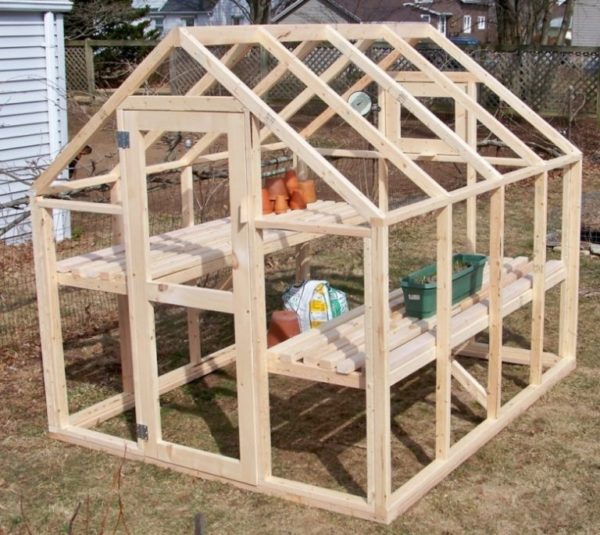

Cucumbers produce the maximum yield when grown vertically. To cover the elongated vines, the greenhouse should be at least one and a half meters high. The optimal design for vertical there will be a greenhouse for growing cucumbers in the form of a hut. The following algorithm is used to make it:

- A 30 cm high base box is knocked together from thick boards.

- Boards measuring 50 x 100 mm are nailed vertically to the center of the end faces. The boards are 170 cm long.

- A ridge board measuring 100 x 50 mm is placed on the top ends of the vertical boards. Its length is equal to the length of the greenhouse.

- Take 50 x 50 mm beams and nail one end to the bottom frame and the other to the ridge board. The horizontal distance between the beams is 50 cm. Once nailed to the ridge board, the tops of the beams are cut horizontally and slightly rounded.

- The ends of the hut are covered with film, polycarbonate, plywood, or simply boarded up.

- To tie up the vines, a garden net is stretched inside the hut.

- The outside of the greenhouse is covered with film or cellular polycarbonate.

Wicker greenhouse

If you don't have the material to make greenhouse arches, you can make them from willow rods. To make a simple wicker greenhouse, follow these steps:

If you don't have the material to make greenhouse arches, you can make them from willow rods. To make a simple wicker greenhouse, follow these steps:

- A 30 cm high base box is made from thick boards.

- A water pipe with a diameter of 25 mm is cut into pieces 15 cm long.

- The pipe sections are screwed to the inner wall of the greenhouse with plumbing clamps every 60 cm.

- For the ridge, take a 50 x 60 mm beam equal in length to the greenhouse. Drill 20 mm diameter holes through it every 30 cm.

- Willow rods with a diameter of 15-17 mm are cut from a nearby bush. The length of the rods is equal to half the arc plus 20 cm.

- To assemble the greenhouse, one end of the rod is inserted into the base tube, the other into the hole in the ridge beam, alternating the right and left sides.

- The outside of the greenhouse is covered with film.

Reviews

Elena, 34 years old

We made a greenhouse out of an old tractor tire. We cut off the sidewalls with a jigsaw and placed the tire on the bed. For the first year, we weighed it down with a sheet of polycarbonate, then we made a wire frame and stretched plastic over it. Cabbage seedlings grow well in this nursery.

Nikolay, 43 years old

I have a greenhouse made from old window frames. Four frames are screwed together to form a box, with a sheet of cellular polycarbonate on top. In early spring, I install it over a bed where I grow early garden flowers. After the last frosts pass, I remove the cover.

The examples given show that make a greenhouse yourself It's within the power of any gardener. The structure can be constructed using any materials you have on hand or in a nearby forest. The resulting work will help you grow a bountiful harvest.