A small garden plot isn't always suitable for a full-fledged greenhouse. A small, compact hothouse is an alternative. Greenhouse designs vary: with or without a foundation, with or without a pitched roof. There are both permanent and portable models. The "Breadbox" greenhouse fits well into the overall look of a small garden plot. An arched plant house will provide reliable shelter for plants if installed correctly.

General description and size options

"Breadbox" is a structure in the form of an arched arc, this is greenhouse with an opening topIt's often made from plastic profiles. They're easy to work with. When making your own, the material is cut with a regular hacksaw. Polycarbonate sheets are used for the cladding. The frame is sheathed according to its openings. When purchasing a ready-made model, all the parts are ready for installation. The main thing is to assemble them correctly, according to the instructions.

There are "bread bin" models that only open on one side. You can buy or make an improved model with two doors. In a double-door greenhouse, the pivot line is located at the bottom of the frame. It can be installed in the middle of a vertical end post.

The dimensions of arched breadbox greenhouses are limited. The width of a house with one sliding roof is 1.3 m. If it has two doors, the maximum width is 2 m. The length of any structure ranges from 2 to 4 m, and the height ranges from 50 cm to 1.5 m.

Design and its features

The "Breadbox" greenhouse consists of three elements:

- foundation;

- two halves (right and left).

The microclimate inside the structure is regulated by lifting the side panel. The lid is secured with hinges. Models available in garden plots have fully opening lids. To ensure full lid opening, the hinge mechanisms are secured to the bottom of the frame. The frame is further secured with a wooden block with several notches cut into it. This mechanism will hold the greenhouse panels in place, preventing them from closing due to wind or other external influences.

The operating mechanism of this greenhouse is based on the breadbox principle, hence the name. The frame can be made from hollow metal pipes, but welding is required.

The following crops are grown in the Khlebnitsa greenhouse:

- strawberries;

- strawberries;

- all kinds of greens and salads;

- carrots;

- beets;

- cucumbers;

- tomatoes;

- flowers.

The tomatoes then need to be transplanted into open ground or into a large greenhouse.

Pros and cons

The "Khlebnitsa" greenhouse has several advantages. The frame can be built by hand using ready-made plans. Plans are available online; simply find them, transfer them to paper, and use them as intended. If you buy a ready-made model, you can quickly install it in the ground, as assembly is effortless. Polycarbonate is a durable and convenient material. If one element is damaged, it can be replaced with another. The structure is lightweight: it can be assembled and moved to another location if needed. It can be used to grow most types of garden crops, with the exception of large and climbing plants.

The design has several drawbacks and operational peculiarities. The hinges need to be inspected and lubricated to prevent jamming and creaking. The greenhouse cannot be left open in inclement weather, as a gust of wind will blow it away. The structure's size is limited, and it cannot accommodate many plants. Single-wing "bread bins" are not always convenient to use.

Despite its shortcomings, this model is a lifesaver for a gardener in the cramped confines of a six-acre plot. With proper care and proper placement, there's no better option for growing flowers, herbs, and berries.

Greenhouses from different manufacturers

There are several ready-made "bread bins" from different manufacturers. A ready-made model can be purchased online or at a gardening store:

- "Novator-mini";

- "Novator-maxi";

- "Snail";

- "Breadbox".

The Novator-mini greenhouse is produced by the Innovation company. This is simple mini greenhouse A single-lid greenhouse. The best place to install it is a small garden plot. It's used for growing seedlings and even melons. The structure is 80 cm high, 1 m deep, and about 2 m wide. The "Novator Mini" is a durable greenhouse that can grow two crops in a single season.

The Novator Maxi is an improved version of the "bread bin" from the same manufacturer. It has two doors and is much taller than the Novator Mini. The frame is painted with a durable, plant-safe dye. Polycarbonate sheets for the cladding must be purchased separately, but the best part is that you don't have to bother with building the frame. The frame is 1.2 m high, 1 m deep, and 2 m wide.

"Snail" is another name for a "bread bin" used by the manufacturer "ROiS." It can be opened from both sides. The greenhouse is 2 m long, 1-2 m wide, and 50 cm to 1 m high. The cross-section of the profile pipe for the base is 20 x 20 mm, and the profile thickness is 1.5 mm. This model is characterized by quick assembly.

Another greenhouse, the "Khlebnitsa," is offered by BZMK. It's wider than the "Ulitka" greenhouse from ROiS, at 1.5 meters. The structure is 2 meters long and 1.5 meters wide. The frame is designed for a cellular polycarbonate covering. This model requires a pre-installed foundation made of wooden beams.

How to prepare a place

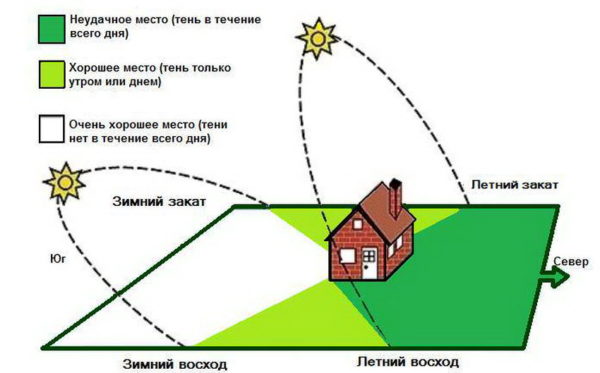

Choosing the right location for your greenhouse is key to its longevity and a bountiful harvest. It's best to place the "Breadbox" on the south side, where it receives the sunlight needed by the plants. Avoid placing tall bushes and trees nearby that create shade.

The greenhouse should be installed as far away from other structures on the property as possible. General guidelines for site selection and installation are as follows:

- the minimum distance between the greenhouse and another object is 5 m;

- distance from the toilet - 25 m;

- The site is first “tested” with a building level, checking for any distortions.

Before installing the greenhouse, the site must be cleared, all stumps removed, and weeds and debris removed. The area must be thoroughly cleaned. If weeds are not removed, they can eventually invade the structure and destroy the plants.

https://youtu.be/nhVcAFrCzMI

Assembling the finished greenhouse

When purchasing a compact greenhouse, it can be transported to the site fully assembled, without disassembling it into its individual parts. A standard Gazelle van is used for transport. Upon delivery, the "Khlebnitsa" is immediately installed in the prepared location. Some models are sold disassembled. As an example, consider the step-by-step assembly of the "Novator Maxi" structure.

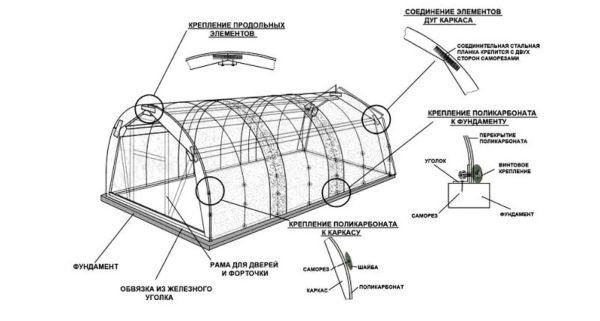

Open the box and carefully remove all the components. You'll find metal ties, plenty of nuts, and bolts. Set aside the side panels and base pieces. The horizontal ties at the ends are threaded and have holes. They can be screwed together and connected directly.

The end panels are shaped like arches or semi-arches. Lay them flat on the floor. Remove the protective layer from the polycarbonate sheets and carefully lay them on top of both arches. When laying the polycarbonate, pay attention to its coating, which protects plants from ultraviolet radiation. Mark it to avoid mixing up the sides. It should face outward, not inward. All sheets should be laid evenly, with their edges flush with the edges of the panels.

You may be interested in:

You may be interested in:The polycarbonate should be screwed to the frame with dowels and any excess material trimmed along the edges. Assemble the side sections using the same principle. Use long horizontal ties to connect the two base elements. There should be five such connections on each side. After joining, apply the sheathing.

The two panels need to be connected in three places: with long ties and covered with PC sheets. Use flat ties to secure them. Now it's time to connect the "side panels" and cover them. The greenhouse base should have a small panel. It has holes through which a long bolt should be inserted. Now install the larger panel and secure it with another bolt. Don't forget to plug the hollow ends of the frame and screw two handles to the panels. The "Breadbox" greenhouse is ready for use.

Making your own "Breadbox"

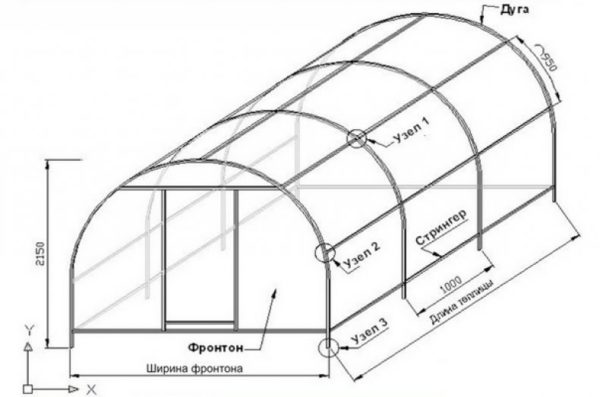

Drawings, readily available online, show that the structure's core consists of two semi-arc-shaped parts. Together, they form an arch. The following are used to construct the frame:

- square plastic pipes;

- metal profile;

- galvanized metal pipes;

- fasteners (suspensions and hinges).

If there is no polycarbonate, the lining is made of polyethylene film, but it's not as durable as PC. If you're skilled in woodworking, you can make a greenhouse frame from timber. The best timber is spruce or aspen. The timber dimensions are 40x40 or 50x50. The timber will need metal support to ensure the hinge mechanism lasts. Simple tools are sufficient: a hammer, a knife, a drill or screwdriver, and a saw.

Working with metal requires certain skills. If you have them, it's best to build the frame from durable galvanized metal profile. The pipe size is 20 cm, with a wall thickness of 1.5 mm. Tools needed include a welder, a hacksaw, and a pipe bender.

Manufacturing a frame from metal profiles

The frame is made according to the following algorithm:

- bend two large arcs of the same size;

- 4 identical parts (20x40 mm) are cut out from the profile;

- the arcs are welded to the lower frame using a welding machine;

- the corner parts of both arcs extend 20 cm (on the back side of the frame);

- strengthen the frame by welding profile sections in the middle of each arc (short and long);

- the active part of the greenhouse is made from two smaller arcs;

- metal corners are welded to the smaller arcs.

To prevent rust, the frame can be painted with durable paint.

Installation of sashes

The doors are the movable elements of the greenhouse. Their frame is made of semi-arches, connected at the top with horizontal metal profiles. It's best to make the cover double-sided to facilitate watering and care of the plants. The doors are attached to the frame so they can be opened and closed at any time. For this purpose, hinged mechanisms with bolts are used. These connect the doors to the working part of the structure. The mechanism that locks the doors in a specific position can be made from any wooden block.

Sheathing with SPK sheets

Polycarbonate sheets They are secured to the base with thermal washers or standard self-tapping screws. Thermal washers are preferred, as they prevent deformation of the material. The mounting hole size is adjusted so that each sheet can move and protects the structure from moisture. The distance between the polycarbonate sheet and each hole should be 40 mm to prevent stress cracking. Maintain a distance of 30 cm between fasteners.

When working with polycarbonate, the air temperature should be at least +10°C. The material is protected along the edges with perforated tape.

Reviews

Vladimir (Torzhok):

"I decided to build two identical greenhouses myself on my property. I took the dimensions online as a template and adjusted them to my needs. Both "Breadbins" are 3 meters long and 1.5 meters wide. We grow cucumbers, tomatoes, and zucchini. Polycarbonate is an easy-to-work-with material. It's easy to cut and use for cladding the frame. I made both frames from galvanized metal profiles for strength and to prevent the structure from being blown away by the wind. When making the lid, I added a sealing gasket to ensure a tight fit to the base. This helps retain heat, especially in early spring when we begin planting the first seedlings."

Irina (Korolev, Moscow region):

"I bought a ready-made greenhouse called "Snail" from ROiS. I'm a small business owner: I grow and sell flowers. My husband assembled a ready-made model according to the instructions. A neighbor advised me to save money and buy a cheaper model with a single lid. I'm glad I didn't listen to her. If I had a greenhouse with one lid, I wouldn't have been able to access the flowers on the other side. Since there are two lids, it's easy to open them, water the flowers, and harvest them for sale when needed. We have a small plot, so this model turned out to be suitable and practically cost-effective."

Vyacheslav (Kazan):

"I used to have a "Butterfly" greenhouse at my dacha, but after a year, both hinges broke. At first, I tried to repair them, but then I decided to buy a different design. I like the "Breadbox" because it's convenient and sturdy: it has strong hinges for the doors, and they're much easier to open. I bought a small greenhouse, and we grow strawberries in it every year. This design is much more reliable than the "butterflies," and to ensure the hinges work properly, I regularly lubricate them with oil."

The "Breadbox" greenhouse is a convenient and practical design. You can build it yourself or buy a ready-made model and customize it to your needs. The key is to assemble the structure correctly and position it strategically on the site.